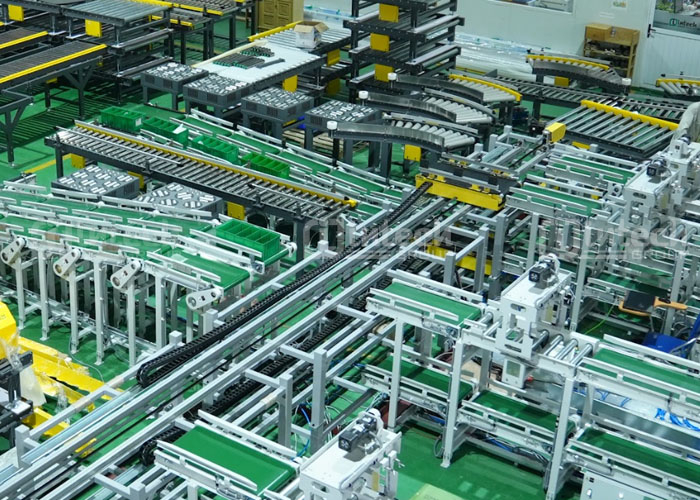

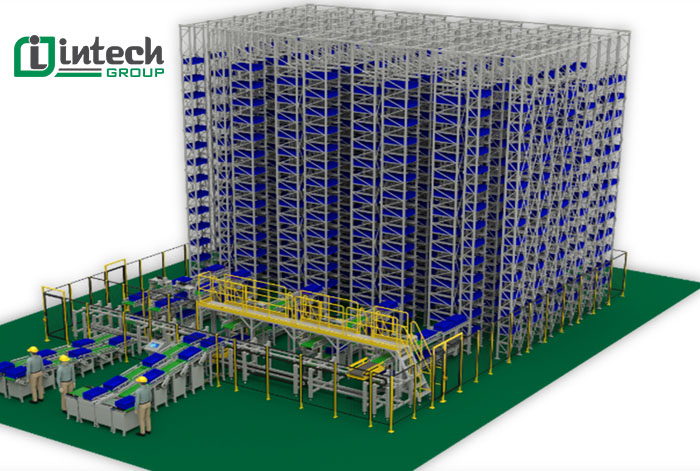

ASRS Miniload smart warehouse is an automatic storage and retrieval solution in modern warehouses, using the ASRS Miniload warehouse system - specialized in managing small to medium sized goods stored in plastic containers or trays.

Some main parameters:

- Conveyor speed 30m/min max load 10kg.

- Goods into 5 crane lines Travel speed: 200m/min.

- Crane parameters Including 2 double cranes and 3 single cranes

+ Travel speed: 240m/min.

+ Input capacity: 300 boxes/ 1 hour.

+ Output capacity: 300 boxes/ 1 hour.

- Warehouse shelf system parameters Dimensions Length 65m x Width 12m x Height 10m.

- Number of storage cells: 44,000 positions

Features of ASRS Miniload warehouse:

-

Structure: Including high-rise shelf system, Miniload robot (shuttle or crane) moving in narrow aisles to store/retrieve goods, plastic boxes or trays to store products.

-

Capacity: Handles multiple shipments/imports per hour, suitable for high-speed requirements.

-

Application: Stores electronic components, spare parts, pharmaceuticals, retail products, etc. with a large number of SKUs but small size.

Advantages:

-

Optimize space: Take advantage of warehouse height, increase storage density.

-

Speed & accuracy: Automatically pick goods on demand, reduce human errors.

-

WMS/ERP integration: Real-time inventory management.

-

Save labor: Reduce the number of operating workers.

-

Increase picking efficiency: Meet the need to bring goods to the work station instead of employees picking.