-

ITR-GD16 Robotic Loading Station

View price quote for ITR-GD16 robot loading station

-

ITR-MD20 Robotic Loading Station

Quotation for ITR-MD20 robot loading station

-

ITR-MD25 Robotic Loading Station

Quotation for ITR-MD25 robot loading station

-

ITR-MD30 Robotic Loading Station

Quotation for ITR-MD30 robot loading station

-

ITR-MD40 Robotic Loading Station

Quotation for ITR-MD40 robot loading station

What is a loading and unloading robot station?

A loading and unloading robot station is a high-end industrial stacking robot, designed to support the movement, lifting, arranging or placing of light goods in warehouses, factories, and logistics facilities. These robots often use automation technology to perform tasks such as picking up light goods from conveyor belts onto pallets such as cartons, bottles, jars, etc., arranging goods efficiently, stably and quickly.

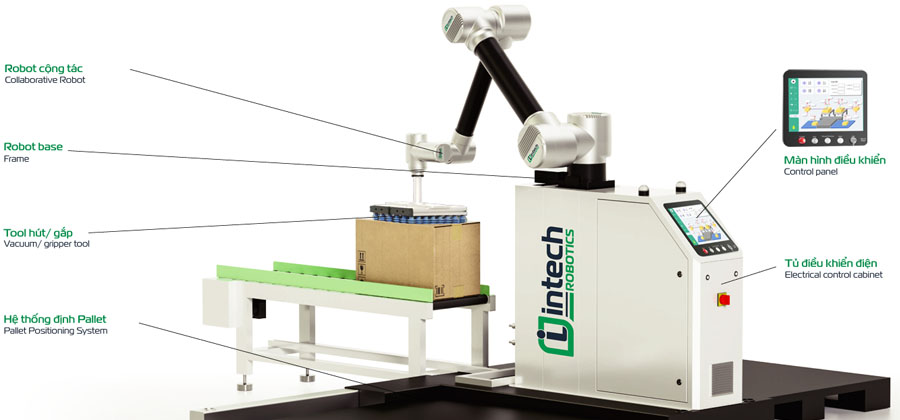

Robot loading and unloading station structure

The robot loading and unloading station is optimally designed for packaging and bagging operations in modern production environments. The structure includes the following main components:

-

Collaborative Robot

International-class heavy-duty collaborative robot – safe, efficient and cost-effective.

-

Robot Base

Convenient mobile base for more flexible application; equipped with 7th-axis lifting column to expand working range.

-

Suction/Grabbing Tools

Lightweight and simple design, strong suction, effective anti-drop – patented product.

-

Operating System

15-inch high-sensitivity capacitive touch screen ITR version 1.0 coordinated stacking robot system

-

Electrical control cabinet

Independent research and development in the company, low energy consumption, high configuration, integrated electrical control cabinet.

Application of robot loading station in factory?

Outstanding advantages of the loading and unloading robot station

- Simple programming: Quick machine setup, intuitive programming software, bilingual support for English and Vietnamese. Even non-professional staff can operate the robot without mastering complex programming languages. Users can learn programming within half an hour and complete the basic program in 1 hour.

- Safe and stable: Equipped with industrial-grade force sensors, high reliability and safety. Support 10 levels of collision detection and protection sensors to ensure safe operation. When a single error occurs, the safety function still operates without interruption.

- Wide application: Widely used in food, pharmaceutical, medical equipment, 3C (computer, communication, consumer electronics), printing and cosmetics industries.

- Flexible production: Easy to switch between different functional features.

-

Support multiple cooperation modes:

Human-machine cooperation

Two-robot cooperation

Multi-machine integration

Support machine-machine and machine-computer cooperation.

- Floor plan: Independent of fixed floor plan, easy to integrate and change layout.

- Economical and practical: Palletizing robot station brings high economic efficiency, average payback period is from 1 to 2 years.

Outstanding features of the robot loading station

-

The machine can complete the installation and adjustment process within just 2 hours.

-

Allows to set up or change new paths in just 5 minutes

-

The easy-to-use stacking robot is capable of stacking 8-10 boxes per minute. (When the pallet reaches the set height, the robot will automatically stop to ensure safety)

-

Supports setting up to 800 stacking paths.

-

The machine is compatible with trays up to 1300mm x 1200mm in size.

-

Special feature allows stacking two different products at the same time, optimizing space and speed.

-

Supports accurate positioning and rotation of labels on products, ensuring packaging quality and product identification.

Benefits of the robot loading station

-

Simple programming

Intuitive, simple and efficient programming. Even non-professional staff can operate the robot without mastering complex programming languages. Can learn programming within half an hour and complete a simple program within 1 hour.

-

Safe and stable

Equipped with industrial-grade force sensors, high reliability and safety. Supports 10 levels of collision detection and protection sensors to ensure safe operation. When a single fault occurs, the safety function still works without interruption.

-

Flexible deployment

Integrated design, light and small in size, easy to move and disassemble. Set up the workstation and change tasks quickly and efficiently.

-

Wide application

Easily switch between different functional scenarios. Supports multiple collaboration modes: Human-machine collaboration; Two-robot collaboration; Multi-machine integration; Collaboration in machine-machine and machine-machine collaboration.

-

Flexible production

Dễ dàng chuyển đổi giữa các tình huống chức năng khác nhau. Hỗ trợ nhiều chế độ hợp tác: Hợp tác người – máy; Hợp tác hai robot; Tích hợp nhiều máy; Hợp tác trong hợp tác giữa máy – máy và máy – máy.

-

Economical and practical

Average payback period of 6 to 12 months, providing a cost-effective automation solution.

Intech Group is the leading supplier of Robotic Loading Stations in Vietnam

The Robotic Loading Station researched, developed and manufactured by Intech Group is an advanced automation solution, helping businesses optimize labor efficiency and minimize operating costs. The system can be deployed quickly within 10-15 days, suitable for many factory models and production processes. We provide full support from installation, technical alignment to operational training, ensuring stable robot operation right at the customer's factory. In addition:

-

Customers can visit Intech Group's factory directly to experience actual operation.

-

Businesses can bring their products to set up and test run on the Robotic Loading Station, helping to evaluate compatibility and application efficiency in actual processes.

-

In particular, Intech Group offers a 30-day trial package, helping businesses verify the performance and stability of the system before deciding to officially deploy it.

Some product images at the factory