INTECH GROUP's SMART FACTORY SOLUTION - ENHANCED PRODUCTION

A Smart Factory or Connected Factory represents a leap from traditional automation to a factory with a fully connected and flexible system of machines and equipment –can use a continuous stream of data from related manufacturing operations and systems to control, analyze and improve to improve productivity, quality in production …

The 4th industrial revolution is taking place very strongly and deeply in many developed countries, it brings opportunities to change the face of many countries in many fields from economy, technology, technology, etc.From technology to healthcare, education, etc. However, here we want to mention in the industrial and manufacturing sectors, this development creates smart factories with superior features and createsbreakthrough in production.

I. WHAT IS A SMART FACTORY?

Smart Factory is a digitized and highly connected production facility based on smart manufacturing.This is an important concept of the fourth industrial revolution, or Industry 4.0.

|

Specifically:

- A smart factory is a term used to describe a manufacturing environment where machines are the main equipment to help improve production efficiency through factory automation, optimization and automation.

- With the smart factory concept you can understand: The production facilities in the smart factory model are digitized and highly connected based on smart production methods.This is the result of the 4th industrial revolution - Industry 4.0.

- Smart Factory is the connection between application software and the system of machines and devices connected to the Internet.Their data is aggregated and analyzed using artificial intelligence (AI) application programming software.

- Smart Factory solution is a leap from traditional automated production to a connected production and continuous data processing.The ability to self-learn from production and business activities helps the system adapt to the new needs of the market.

- The most important thing: Smart Factory has the ability to develop and improve in accordance with the needs and development of businesses and factories.Whether it's market expansion or new products or meeting operational and maintenance needs,...

A connected smart factory cannot lack an MES system to coordinate operational functions.Many functions and features are provided by MES that IIoT (Industrial Internet of Things) can hardly replace.The MES system is integrated by technologies such as: augmented reality, cloud computing, artificial intelligence, Auto-id.... MES is also effective for analyzing KPIs and OEE in production.

II.OVERVIEW OF SMART FACTORIES

There are many ways to define smart. It depends on each evaluation reference system, but from a production perspective, a Smart Factory: is a factory that applies technological achievements, helps to solve production problems, in order to improve productivity. production, optimize costs, reduce costs, improve product quality..

|

Accordingly, along with the development of technology, the model of smart factory of each period will be different.

According to the historical process, it can be seen that the smart factory goes through the following stages:

1. Smart factory in the 1.0industrial revolution

Using mechanical tools to improve production efficiency, and using steam engines to replace human or animal power. The application of these achievements has increased production efficiency by 4 to 8 times.

2. Smart factory in the 2.0 industrial revolution

The invention of electricity, and the electric motor.The factory applies these technologies in many applications: lighting, machinery using electric motors such as machine tools, production lines, electric heating devices... Creating a breakthrough in production methods, in this period, the mass production lines appeared.

3. Smart factory in the 3.0 industrial revolution

The advent of semiconductor electronic chipscreatessmart computers and open an era of information technology,underlying all these modern manufacturing platforms.Computers & application software are indispensable tools in every factory.From design, planning, production organization, data storage, information processing, to payment, communication...

Along with computers, the development of logic controllers, Microcontrollers are integrated in machines to create modern sophisticated automation machines and systems, replacing humans in many stages as well asfield.This improves production efficiency, quality, and creates more sophisticated products

4. Smart factories in 4.0 era

Inheriting the features of 3.0smart factories.With computers, data digitization, automated machines, camera and sensor systems.It is a revolution that profoundly changes production methods.Although it has brought production to a new level, there are still some problems with it.Automated systems take care of separate stages of production.Operational roles that monitor, maintain, and manage as well as provide input still need a human role.The more modern the machine, the higher the productivity, which means that the input data has to be processed more complex.Just not timely information can be a large amount of goods considered as waste products can be produced leading to huge losses.

For example: To plan production for laser cutting machine.The planning department has to confirm the order, the inventory data, the actual production capacity of the machine, the current plan of the machine, the maintenance plan of the machine, etc. A lot of information needs to be confirmed and processed.production plan has just been released.In addition, the information can be very difficult to control, for example, information about the actual performance of the machine (For an accurate assessment, a lot of data is needed).Or inventory information, can only evaluate the information of goods in stock, goods in the process of production, shipping, defective goods..etc.Thereby we can see the problem of existence of production is:

|

- Time consuming in the middle stage of data processing.-> extended production time

- Accuracy of information: May pose a risk in production.

- Loss of labor to handle the intermediate stage.

- Not making full use of the machine's performance…

4.0 Smart Factories

Applying the achievements of industry 4.0 with IOT, AI, BIG Data platforms… Objects in the factory are connected to each other (IOT).With the development of current sensors, almost all the necessary information to describe the system can be collected and digitized (Digitalization), all the information and data of the components (Things).Instantly updated to the common data system (Big Data).The data is automatically synchronously processed from input to output, ensuring continuity, and adaptability in the factory's production chain.At the same time, people can almost completely and instantaneously control the entire production chain of the factory.

III. BENEFITS OF 4.0 SMART FACTORIES

The smart factories has distinctive features such as:

- Smart Factories are proactive systems: capable of meeting and adapting to the strict requirements of the market.Humans can control production machines and equipment, monitor and digitize operations to improve production efficiency, and promptly handle problems when problems arise.

- Smart Factories - Flexibility and agility (Agile): Enterprises can actively develop their smart production systems according to market needs, expanding into new markets flexibly.

- Smart Factories - Connected: Smart Factory has the ability to intelligently connect all machines, helping businesses create a more efficient supply network.

- Smart Factories - Transparent: Smart data collection network helps businesses get the database to make more accurate decisions.

- Smart Factories - Optimized: Smart Factory helps people not to interfere too much in the production system but still ensure efficiency.

As mentioned in the previous section, a smart factory applies technology to solve production problems.Each business will have its own problems, so the benefits of smart factories will not be the same.Here are some examples of the benefits of smart factories:

1. Higher business productivity

How is a smart factory more efficient?It relies on automation to complete the processes, the production becomes more automated, requiring less human intervention.As production relies heavily on people doing the work, there are many ways production can stall: Labor shortages, days off, vacations, sick days, necessary leave, and more.There is also an increased risk due to safety concerns.

Machines are different, they don't need rest.It can work for hours or days.In fact, automated machines can be programmed to operate 24/7.That makes the process faster and cheaper.

Instead of routine, manual production tasks – employees can be freed up to analyze data, create more valuable customer experiences, and innovate.

Packaging automation |  Transport automation |  Classification Automation |  Logistics automation |

2. Higher customer satisfaction

Another benefit of a smart factory is a higher level of customer satisfaction.Why is that?

Data-driven smart manufacturing.That data comes from a variety of sources: customers, internal data, data generated by connected products, and more. With that information, you can predict demand for your products.You can see if a particular item is selling well and increase production in real time.With the same token, you can scale down the production (again, in real time) of an item that isn't selling well

You can also ensure flexibility by creating a quick configuration of your device.It can be easily adapted to produce different products.With agile configuration, you save time and money as there is less disruption to adapting to a new production schedule.

3. Better product quality control

|

The above problem will be solved with a smart factory solution, where manufacturers can control quality proactively.In this model, there will not even be a QC department, because people have applied IoT to monitor and control the product creation process.

In the smart factory model, devices such as temperature, pressure, speed, air flow and humidity will be monitored in real time to identify when parameters tend to exceed specified calibrations.The system will then issue a warning soon that the Product or component may not be up to standard.Not only that, this measurement and warning also helps managers to quickly determine the exact source and time of the nodal point, where the problem first occurred, from there, taking remedial measures.

Not stopping there, instrumentation and analytics in the smart factory model can track the results of critical production steps, by measuring or inspecting finished components or products.to ensure they conform to specifications.Early detection of defects in the production process will help businesses reduce the running time of the next components, thereby reducing production costs.

|

4. Predictive maintenance

Smart factory models with better status visibility can predict and help manufacturers resolve maintenance issues before they lead to downtime or product quality issues.

For example, sensors attached to a machine or device can send real-time performance monitoring data and automatically generate repair plans, from which businesses can build optimalproduction plans.

5. Improving the efficiency of machine use

When the machines are modeled, the data is collected timely and completely, people can easily control the machine's performance.The causes affecting the performance can then provide solutions to improve the performance of the machine.

In addition, when the whole production chain is modeled and controlled, Humans can easily detect production bottlenecks and make appropriate adjustments and improvements to improve not only machineproductivityin particular, but system-wide performance in general.

IV.SMART FACTORY STRUCTURE

According to the above analysis, the smart factory model will be different depending on the period.

However, according to the analysis of experts for developed countries such as Europe, America and some Asian countries,the smart factories of the countries are now at the end of 3.0 phase and the beginning of4.0 phase.

So what will the structure of the 4.0 smart factory look like?

|

1. Automation and digitization of information

3.0 model with modernproduction base based on automatic machines and information technology applications.Manufacturing has become more efficient and smarter.

As sensor technology develops, more and more modern sensors can simulate most states of objects. From the simplest information like yes, no, quantity, and color. To the more advanced sensors that can record temperature and humidity parameters, modern cameras can recognize the shape, number as well as product defects... With those sensors most of the conditions The state of objects, the process of "physical world" production are all described by digital signals.

2. Connectivity (IIOT)

Through a cyber-physical network, an online communication network between machines, organized as a social network.Simply assigning a network address, they will create an IT link with the electromechanical components, then communicate with each other through the network infrastructure.

The information collected by sensors is constantly sharing information: About current stock, about problems or errors, about changes in orders or demand levels.The production process and lead time are coordinated with the goal of increasing efficiency and optimizing production time, capacity and product quality in all stages of production.

3. Big data

Based on continuously updated data from objects,all the states of the processes are simulated in real time. At this time, the line between the real world and the virtual space is almost blurred. Humans can almost control, and interfere completely and instantaneously, the machines, objects and processes in the factory.

In addition, the data center is also a source for analytics to show trends of: quality, design, breakdown...

4. Artificial Intelligence

All data is modeled, through which AI applications will analyze past data, to give warnings, trends ... and then more advanced will make auto-adaptationadjustments.

For example: During the production of goods, any defect data will be remembered, when a new production process is available, the AI application will analyze the past data compared with the product production processnew products, giving feedback to the production design department... From there, there are timely changes to reduce time as well as avoid errors that cause economic losses.

V. STEPS TO BUILD A SMART FACTORY

1. Factory model positioning and orientation:

Perhaps the first step to building a smart factory is to determine what level your factory is at.From there, decide the appropriate intelligence for the business scale.

This job is strategic, to do it requires businesses to have a long-term vision, carefully analyze the factors of opportunities and threats, and at the same time must have a certain potential and determination.

2. Problem identification & improvement methods

After all, technology, no matter how developed, is just a tool to improve production.In order for the tool to be used and promoted effectively, the factory itself must have specific improvement methods.

Information technology, positioning, 3G network... are the foundations and achievements of technology.But only then, it cannot create models like Grab, Uber... Developers themselves need to grasp the problems of society, design a way to solve problems based on those problems.technological achievements to create successful business models like today.

In manufacturing, too, to build a smart factory, it is necessary to identify production problems, and to have methods to solve them. And technology is the tool in the methods, tech-savvy people will choose the optimal method to solve their problems in the most effective way.

3. Smart factory solution provider

It can be said that the role of people is extremely important, to come up with a solution for a smart factory, it not only requires people who understand production, have knowledge about production improvement, and notindispensable is technological capacity.

Several factors affect smart factory implementation:

- Financial plan

- Synchronization between man and machine

- Technology platform

- Industrial Robotics

- Supply of automation equipment

- Deployment unit

The outstanding facilitators of smart manufacturing technology such as:

- Artificial intelligence

- Production status tracking software

- Blockchain technology in production

- Industrial Internet

- Network security

- Industrial Robots

INTECH GROUP with a long-term team working in large production environments such as SAMSUNG, CANON… With expertise in automation and production technology.Participate in many factory improvement projects.With our existing experience, we are confident to bring you the most effective and optimal smart factory solutions.

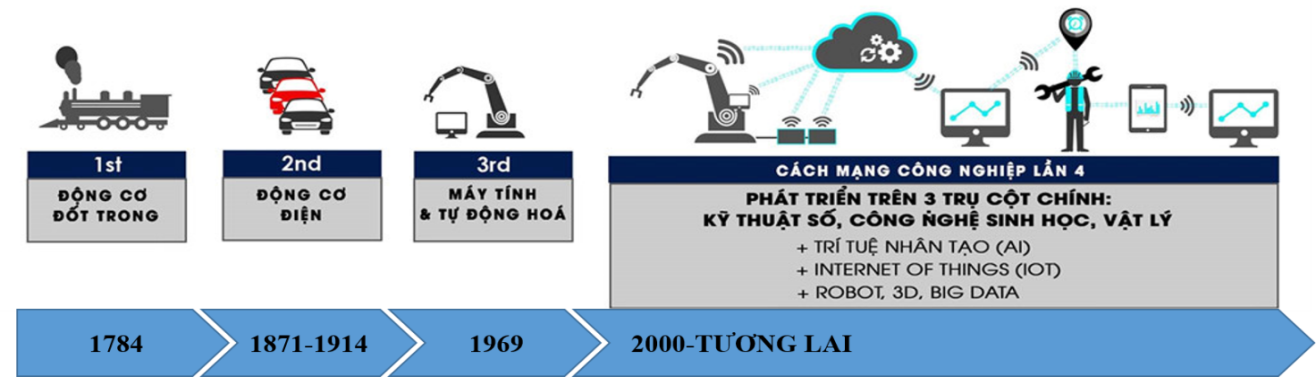

DEVELOPMENT OF INDUSTRIAL REVOLUTIONS

|

4.0 Industry is the industrial revolution in which it combines technologies, blurring the lines between physical, digital and biological, forming a unified whole that is intelligently and sophisticatedly connected and linked.

In human history, there have been 3 industrial revolutions and now the 4th industrial revolution called "Industry 4.0" is taking place.

1. The first revolution: Invention of the internal combustion engine in 1784;

2. The second revolution: Invention of the electric motor;

3. The third revolution: It is the birth of computers and automatic systems and automatic machines;

4. The fourth industrial revolution "Industry 4.0" has taken place since the 2000s, is the era of artificial intelligence (AI), Internet of things (IoT), Robots and Big datawith the goal of creating smart factories.

How to apply 4.0 technology?

- As an inevitable rule, in order to apply 4.0 technology, 3.0technology must be perfected, ie perfecting technological processes, perfecting machines and automation systems.

- At the same time, the core elements of 4.0 technology such as "Artificial Intelligence (AI), Internet of Things (IoT) and Big Data" are applied andoperated.In addition to these three core elements, it is indispensable to apply 4.0 technology: Blockchain, cloud computing and edge computing, cyber-physical systems (CPS), cognitive computing(cognitive computing), Robots, the internet or 5G.

- In addition, the human factor is also very important to catch up and successfully apply the technologies in the 4th industrial revolution "Industry 4.0", from the leadership to the employees must understand the importance of the technology.important, to boldly innovate, to paste and discard the old ones, the inappropriate ones, etc. to be successful in implementation;

Expectations and benefits of 4.0Industry

- Up to now, it is undeniable that the benefits and effects brought about by the first step of the industrial revolution 4.0, it has profoundly affected almost all fields, creating a new face for many businesses.

- In fact, one of the biggest expectations of the 4.0 technology era is the potential to improve the quality of life and raise the income level for the world's population, with a gradual shift in the labor structure, from manual labor to mental labor.

- Especially, the 4.0 industrial revolution also creates a smart production platform with the "Smart Factory", which will create a breakthrough in production, bringing great values to humanity in the new era.