Automation solutions for refrigerator production lines.

10-01-2026 36

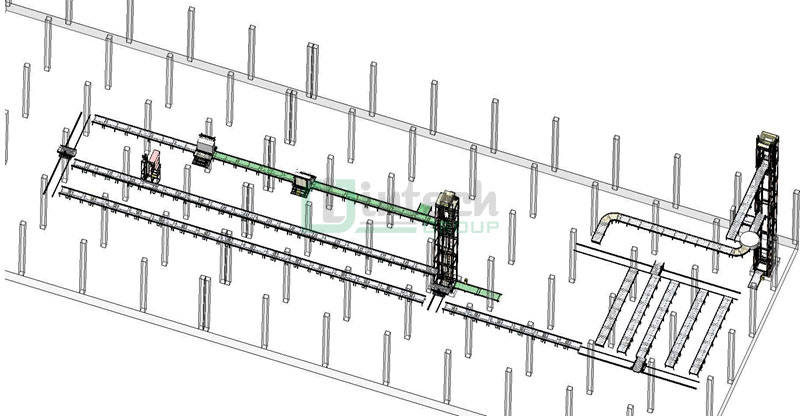

Intech automated cargo lift technology – optimizing the flow of goods transportation in refrigerator manufacturing plants.

The automation solution for refrigerator production lines is a synchronized integration of electromechanical equipment, industrial robots, and control software to optimize the entire production, transportation, and storage process within the factory. This solution helps businesses increase productivity, tightly control quality, and reduce reliance on manual labor.

In modern manufacturing plants and warehouses, transporting products between floors is often a bottleneck when automating the production line.

Overview of automation in refrigerator production lines.

Challenges Commonly Faced by Refrigerator Manufacturing Plants

In large-scale refrigerator manufacturing plants, especially multi-story models, businesses face numerous challenges in transportation and production synchronization:

Imbalance in Production Rhythm Between Floors

Raw materials, semi-finished products, and finished products must constantly move between production floors. When transportation relies on manual methods or traditional equipment, the feed rate is uneven, causing localized bottlenecks or line interruptions, directly affecting the overall production rhythm.

Increased Labor Costs and Waiting Time

Manual transportation or the use of conventional elevators requires a large workforce and generates waiting time between stages. This not only increases labor costs but also prolongs the production cycle, reducing the ability to fulfill orders.

Reduced overall factory operational efficiency

The lack of synchronization in internal logistics prevents the production line from utilizing its full design capacity, reducing OEE, increasing the risk of errors, and making it difficult to control the flow of materials between production areas.

In refrigerator production lines, processes such as component supply, assembly, semi-finished product transfer, finished product transport between floors, and warehousing require high precision, heavy loads, and continuous operation. Automation systems allow seamless connection between production areas through conveyor belts, lifts, AMR/AGV autonomous robots, and automated workstations, ensuring stable and timely material flow.

Solution: Intech Group's Lifter

The automated lift developed by Intech Group is the optimal solution to help businesses fully automate vertical transport, seamlessly connecting production floors. The system enables the rapid, accurate, and safe transportation of raw materials, semi-finished products, and finished products, thereby:

Intech Group's Lift Solutions

-

Balance production pace across different levels

-

Significantly reduce labor costs and downtime

-

Improve overall operational efficiency and line stability

-

Optimize space and long-term operating costs

Key Features of the Automation Solution for Refrigerator Production Lines

The automated material handling system implemented by Intech Group is designed with a robust structure, meeting the requirements for continuous operation in heavy industrial environments:

-

High-grade powder-coated steel frame: The frame is made from high-strength steel, coated with powder paint to increase durability, resist corrosion, and ensure a long lifespan in factory environments.

-

Integrated elevator cabin with diverse conveyor systems: The cabin can flexibly integrate roller conveyors, belt conveyors, or chain conveyors, suitable for various product types and transport processes in refrigerator production lines.

-

High operating efficiency: Stable lifting speed of 15–30 m/min, meeting the requirements for fast material feeding, reducing waiting time, and optimizing production pace between floors.

-

High Load Capacity: Maximum lifting capacity of up to 2 tons, allowing for safe transportation of large and heavy containers, pallets, or products.

-

Standard Industrial Power Supply: Uses 3-phase 220/380VAC voltage, easily integrated with the factory's existing electrical infrastructure.

Wide Application Range:

Intech lifting platforms are effectively used in refrigerator manufacturing plants, smart warehouses, and automated logistics systems, optimizing vertical transport, enhancing safety, and improving overall operational efficiency.

Thanks to its flexible scalability and integration with manufacturing process management systems (MES) and warehouse management systems (WMS), the automation solution for refrigerator production lines not only meets current needs but is also ready for the future direction of smart factories. This is a crucial foundation that helps businesses enhance their competitiveness, stabilize product quality, and achieve sustainable development in the refrigeration industry.