Color Product Sorting System: Applications & Classification

27-10-2025 5

Color product sorting systems are becoming an indispensable technology to help businesses improve productivity and accuracy in quality control processes in the era of automation. This system uses optical sensors, color cameras and image processing algorithms to quickly and accurately identify and classify products based on color.

This system is widely used in industries such as food, pharmaceuticals, electronics and packaging. Join Intech Group to learn more about the concept, operating principle, advantages and practical applications in the content below!

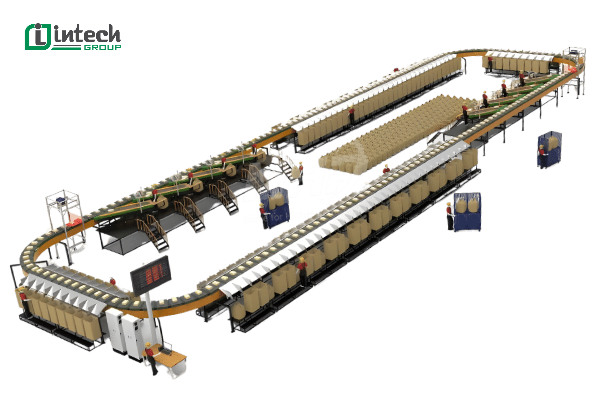

Intech Group's Crossbelt parcel sorting system provides high efficiency, low energy consumption and reduces error rate when sorting.

What is a color product sorting system?

A color product sorting system is part of an automated material handling line, designed to sort products based on specific criteria such as color, weight, size, barcode, production batch, production date, or delivery location.

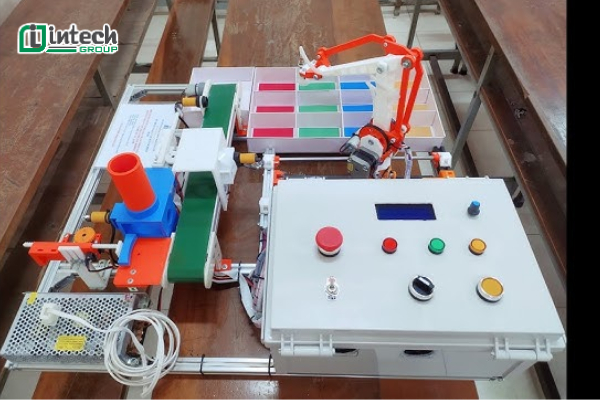

This system works thanks to a combination of optical sensors, color cameras and intelligent control software, helping to identify and classify products with high accuracy without manual intervention. During operation, the robot picks and places products and the automatic conveyor will move and arrange the goods in the correct storage location or corresponding processing area.

Product classification system by color

Outstanding features of the product classification system by color

The outstanding feature of the product classification system by color lies in its ability to flexibly classify according to many different criteria such as color, size, height, weight or unique identification features of each type of goods.

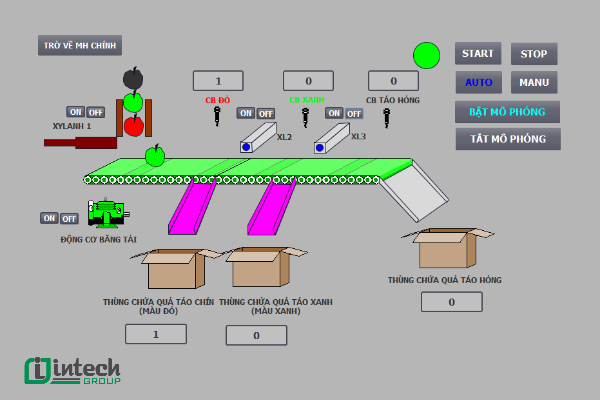

The system operates based on advanced machine vision technology, combined with high-resolution industrial cameras to accurately identify each product. Image processing algorithms will analyze and issue automatic control commands, helping robots or conveyors to bring products to the correct corresponding location.

Through the automatic product classification line, goods are guaranteed to be uniform and stable in quality, shape and weight before being packaged or shipped. Not only does it help minimize human errors, the system also supports manufacturers to quickly track, store and retrieve product information to meet the strict requirements of modern production models.

Outstanding advantages of the product classification system by color

The product classification system by color can combine Pick to Light technology, conveyor belts, smart conveyor belts and visual sensors to quickly and accurately identify, classify and arrange products.

- The system is capable of working continuously at high speed, helping to shorten the time for sorting and processing orders.

- Thanks to color sensors and industrial cameras, products are classified accurately, minimizing errors during operation.

- The integration of conveyor belts, conveyor belts and Pick to Light technology helps reduce the number of operating personnel, while increasing productivity and saving production costs.

- The system can work 24/7 without interruption, suitable for large-scale production lines.

- Reduce the risk of work accidents, while eliminating paperwork, helping to optimize information management.

- Compact design, easy to integrate with existing conveyor systems in the factory.

- The system automatically records product data in real time, helping businesses effectively manage goods and avoid backlog.

The role of color product sorting systems in modern production

Here are the prominent roles of this system in actual production:

Reduce product errors, improve productivity and operating speed

The product sorting system operates stably with the ability to sort and pick products at high speed thanks to the application of color sensors and industrial cameras, products are classified accurately according to each criterion, helping to maintain stable productivity and quality.

In addition, the system can also check and automatically detect overload conditions, ensuring continuous operation, contributing to building smart production lines and warehouses for businesses.

Perform complex and continuous operations

The picking and sorting machine is equipped with force sensors and image sensors, allowing complex sorting processes to be performed. The system can automatically measure, collect data and improve performance in real time, helping to optimize sorting quality and processing speed.

Cost savings and material optimization

By automating the sorting process, businesses can significantly reduce labor costs while minimizing errors in manual operations.

Improve business competitiveness

The product sorting system helps ensure consistent output quality, meeting export standards and strict market requirements. As a result, businesses can increase brand reputation and enhance competitive advantages in domestic and foreign markets.

Easy installation and flexible integration

With a compact design and flexible configuration capabilities, the system can be quickly installed on existing production lines, reducing configuration time by up to 16 times. In particular, it can be easily integrated with pick and place robots, conveyors and other automatic equipment, helping to create a synchronous and highly efficient production system.

The most popular product classification systems in 2025

Depending on the characteristics of the goods and operational requirements, businesses can choose different classification technologies. Below are the 4 most popular product classification systems in 2025.

Product classification system by barcode (Barcode/QR Code)

The system operates based on scanning Barcode or QR Code to identify detailed product information such as production batch, model, production date, order or delivery location.

Thanks to the application of high-speed code scanning sensor technology, this system can achieve a productivity of 10,000 products/hour, 3-5 times more efficient than manual methods, while reducing errors almost completely. This is an ideal solution for automated warehouses, distribution centers and automated packaging systems.

Product sorting system by weight

This system is designed for the food, seafood and agricultural industries, where weight is a key factor in determining the quality and standards of goods. Weight sensors (load cells) are integrated in the sorting conveyor, helping to measure product weight quickly, accurately and automatically flow to the appropriate locations.

.jpg)

Color Sorting System

As the key word in the automation trend of 2025, the color sorting system uses machine vision technology and high-resolution industrial cameras to identify and process product images, suitable for many industries such as agriculture, food, oil and gas, pharmaceuticals or recycling. With a capacity of 0.8 - 1.5 tons/hour and an accuracy of up to 99%, the system helps eliminate color-defective, tone-wrong, or substandard products, ensuring consistent quality before packaging.

Product size sorting system

The sorting speed can reach 3–5 tons/hour (equivalent to 1,000–1,100 products/minute), ensuring high efficiency and stable operation. Applied in the fruit, food, agricultural products or electronic components industry, this system operates based on optical sensors or size measuring cameras. This solution helps businesses automate the inspection process, unify the size of goods and improve accuracy in packaging and transportation.

How to choose the right color sorting system

An effective system not only helps improve productivity but is also an important foundation in developing smart warehouses and smart factories to optimize the entire operating process.

Step 1: Identify specific goals and challenges

Enterprises need to clarify the goals of sorting - for example: increase processing speed, reduce errors, or fully automate the production line. Understanding the current challenges will help you identify the right technology solutions needed.

Step 2: Learn about modern sorting technology

Advanced sorting systems often use color sensors, vision cameras, combined with industrial robotic arms and automatic conveyors to ensure high speed and accuracy. Comparing these technologies will help you choose the system that best suits the specific characteristics of your product.

Step 3: Analyze product characteristics

For fragile or high-value products, it is necessary to choose more sophisticated recognition technology and sorting mechanisms such as size, weight, shape and material properties to ensure safety during transportation.

Step 4: Evaluate throughput and factory space

Determining the operating capacity and available space in the factory or smart warehouse helps you choose a sorting system with the right scale and speed, avoiding wasted investment.

Intech Group provides the leading product classification system in Vietnam

With more than 14 years of experience in the field of industrial automation, Intech Group is a pioneer in providing modern, accurate and cost-optimized product classification solutions by color, weight, size for businesses.

Superior quality: Products are manufactured on modern production lines, ensuring durability and high performance.

Flexible customization: Solutions are designed according to the characteristics of each industry and each type of product.

Team of experienced technical experts: Always ready to advise and support quick implementation.

Optimal cost - Sustainable efficiency: Bringing long-term value to businesses in the journey of transforming to smart factories and warehouses.

At Intech Group, product sorting systems are flexibly designed and customized according to each business's requirements, easily integrated with product picking robots, conveyors, Pick to Light conveyors or smart warehouse management systems (WMS) to provide comprehensive solutions for modern production and logistics automation. Contact us now for advice and support via Hotline 0966.966.032 - 0983.113.387.