Details of popular beer production lines today

14-09-2025 40

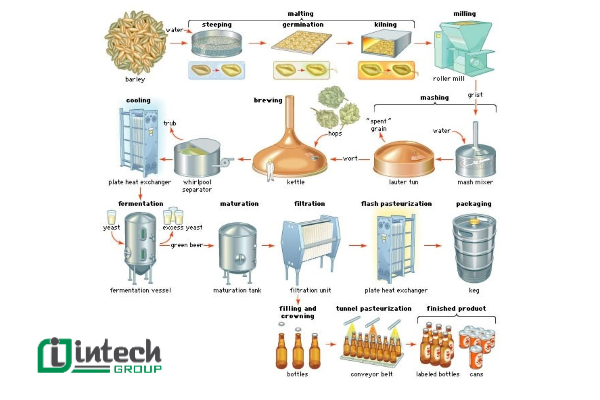

The beer production line is a modern technological system designed to ensure the brewing process is efficient, from raw material selection, grinding, cooking, fermentation to packaging, each stage is strictly controlled to preserve the characteristic flavor of the beer.

Currently, the food and beverage industry is growing, understanding the beer production line not only helps businesses optimize the production process but also creates a competitive advantage in the market. In the following article, Intech Group will provide you with information about popular beer production lines.

The beer and alcohol market in Vietnam today

The beer, alcohol and beverage industry in Vietnam is growing strongly, but also faces many challenges. One of the biggest difficulties is human resource management, especially in beer production lines that require a large number of highly skilled workers. In addition, businesses must also ensure labor safety standards, food hygiene and reasonable division of labor to maintain production efficiency.

In that context, the application of automatic and modern beer production lines has become an inevitable trend. Not only helping to streamline staff and increase productivity, these production lines also meet quality requirements, diversify products and bring consistent quality. In the world, the beer industry is strongly reviving with many new product lines such as non-alcoholic beer, premium beer, herbal beer, etc. In Vietnam, many factories are also investing in new production lines to keep up with the trend, contributing to enriching the market and enhancing domestic brands.

Main ingredients in the beer production line

Beer is a light alcoholic beverage, created from a natural fermentation process and contains many nutrients that are beneficial to health. In addition to providing energy, beer also contains many enzymes, especially the enzyme Amylase, which helps support effective digestion. Thanks to its characteristic aroma and the amount of low molecular dextrin sugar remaining after fermentation, beer has become a popular drink worldwide.

In the modern beer production line, the main ingredients include malt, hops and purified water. In addition, depending on the formula and characteristics of each brand, businesses can add rice, enzymes, yeast and some other additives to adjust the flavor, color and alcohol content accordingly.

Nowadays, most factories apply automated beer production lines to strictly control from the stages of grinding raw materials, cooking, fermenting to bottling and packaging to ensure consistent quality, improve productivity, and save operating costs.

Modern beer production line operation process

Today's brewery production lines are designed in a closed, highly automated model, helping to strictly control quality and ensure hygiene throughout the entire process. A complete process includes the following main stages:

Stage 1: Raw material preparation

The process begins with the grinding of malt, a key ingredient in beer production. A specialized grinder will crush the malt grains but still keep the shell intact, ensuring efficiency for the following cooking and filtering steps.

Stage 2: Cooking and filtering the residue

The crushed malt is cooked with water to form a gelatinized mixture, breaking down the original solid structure. After that, this mixture is put into a modern filter pot (like Pegasus) to separate the residue, retaining the sugar solution. Today's filtering equipment integrates an automatic cleaning mechanism, improving efficiency and saving time.

Stage 3: Boiling and adding hops

The wort is boiled and hops are added, an important element that creates the characteristic flavor of the beer. Depending on the recipe, the manufacturer can add the flowers at once or in several times to control the flavor more delicately.

Stage 4: Sedimentation

After boiling, the beer is transferred to the Whirlpool equipment to perform the sedimentation process, completely removing impurities and remaining hops. Thanks to modern filtration technology, even when using pelleted hops, the process is still fast and effective.

Stage 5: Fermentation

The wort is cooled and enzymes are added to stimulate the fermentation process with yeast. The amount of yeast is adjusted appropriately, avoiding the lack or excess of yeast affecting the flavor of the finished product.

Stage 6: Fermentation

This stage requires maintaining the exact CO2 pressure in the fermentation tank. Beer production lines often incorporate automatic gas regulation systems to ensure that excess CO2 is released properly, keeping the beer at its optimum freshness.

Stage 7: Filtering sediment

After the brewing process, the beer is thoroughly filtered to remove impurities, excess yeast or sediment. The filter uses a microbiological filter with extremely small pore sizes to preserve the color and clarity of the beer.

Stage 8: Packaging

Finally, the filling and packaging step, the beer is put into cans or bottles in a CO2-controlled environment to limit oxidation. Thanks to this, the beer does not foam and still retains its fresh flavor when it reaches consumers.

Main equipment in the beer production line

A modern beer production line cannot lack a system of specialized equipment designed to automate and optimize each stage in the beer production process. Below are some important equipment in the line:

- Malt grinding equipment: Used to grind malt grains before cooking, ensuring that the shell is kept intact to support the filtering process well.

- Cooking system: Including cooking pot, filtering pot and boiling pot, this is the heat treatment area to gelatinize, extract sugar and remove excess residue.

- Hệ thống nấu: Bao gồm nồi nấu, nồi lọc và nồi sôi, đây là khu vực xử lý nhiệt để hồ hóa, chiết xuất đường và loại bỏ bã thừa.

- Sugar and hop boiling equipment: Helps extract flavors and essential oils from hops, creating a characteristic aroma for beer.

- Filter tank and settling tank (Whirlpool): Used to filter out residue, solids and flower residue after the cooking process, ensuring clear and clean beer.

- Rapid cooling system: Reduces the temperature of the beer after cooking, preparing for the fermentation stage.

- Extraction and fermentation equipment: Includes fermentation tanks with the ability to control temperature, pressure and CO2 to create ideal conditions for yeast to grow.

- Beer filtration equipment: Completely removes residue and excess yeast, maintains the color and clarity of the finished beer.

- Pasteurization equipment: Ensures food hygiene and safety, kills bacteria and prolongs storage time.

- Carbonization equipment: Adds CO2 to beer according to quantitative standards to increase refreshment and characteristic flavor.

- Bottling or cartoning equipment: Integrated with labeling machines, automatic packaging systems, conveyors, conveyor belts and robot loading stations, helping to optimize speed, reduce labor and ensure consistent finished products.

.jpg)

With a synchronous equipment system and modern automation technology, the beer production line not only increases productivity but also ensures stable quality, meeting the increasingly diverse market needs.

Benefits of applying automation to the beer production line

Investing in an automated beer production line is not only a trend but also a vital factor that helps businesses improve efficiency and product quality. Below are the outstanding benefits that automation brings:

1. Increase operational efficiency without increasing costs

The application of automation helps optimize every stage in the production line, factories can increase productivity without expanding human resources or investing too much in operating costs. The production time of a can of beer takes only a few seconds, allowing businesses to quickly respond to market needs and improve competitiveness.

2. Ensure consistent quality and easy to scale

Automation helps to strictly control technical parameters throughout the production process, from temperature, time to pressure and raw material ratio. Thanks to that, beer always retains its characteristic flavor and stable quality so that factories can easily expand their scale without affecting the consumer experience.

3. Enhance labor safety

In the automatic beer production line, most of the stages are performed by machines, minimizing direct human intervention. Workers mainly take on the role of monitoring and adjusting the system, helping to limit the risk of work accidents and improve safety at the production site.

4. Save energy and raw materials

The equipment in the line is programmed to operate optimally in terms of capacity and efficiency, helping to reduce raw material loss, save electricity, water and other resources. This not only brings economic benefits but also contributes to building an environmentally friendly production model.

5. Ensuring food hygiene and safety

Automation helps eliminate many manual steps that pose a risk of contamination, while ensuring a closed and consistent production process. This is an important factor in maintaining food hygiene and safety standards, especially for beverage products such as beer.

Investing in a modern and automatic beer production line not only helps businesses increase productivity, save costs but also improve quality and create sustainable competitive advantages in the market. Intech Group is a leading provider of automation line solutions in Vietnam. With a team of experienced engineers, with a quick design, implementation, installation and warranty process, it will help your business optimize efficiency, improve production capacity in today's competitive market.