Product sorting system by height: Structure and application

27-10-2025 3

The height product sorting system is an automatic solution that helps businesses arrange and control products based on size, ensuring high accuracy and fast processing speed. This system uses height measuring sensors combined with smart controllers, helping to optimize the packaging, inspection and transportation processes in the factory.

Intech Group provides a modern product classification system that is easy to integrate into the production line, suitable for many different industries. Let's find out more in the following article.

What is a height product classification system?

A height product classification system is an automatic solution used to identify, measure and classify products based on the height of each object. This system is designed to replace manual inspection, helping to ensure that products meet technical standards before moving to packaging or warehousing.

The system's operating mechanism is based on a height sensor or 3D camera, collecting product size data while moving on an automatic conveyor. Then, the central controller (PLC) will process the information, compare it with the preset value and command the flow mechanism (sweeper, cylinder, weighing conveyor, loading robot, ...) to put the product in the correct corresponding position.

Structure of the height product sorting system

A complete height product sorting system is made up of many parts that are closely linked together, ensuring a stable, accurate and continuous operation process. The main components include:

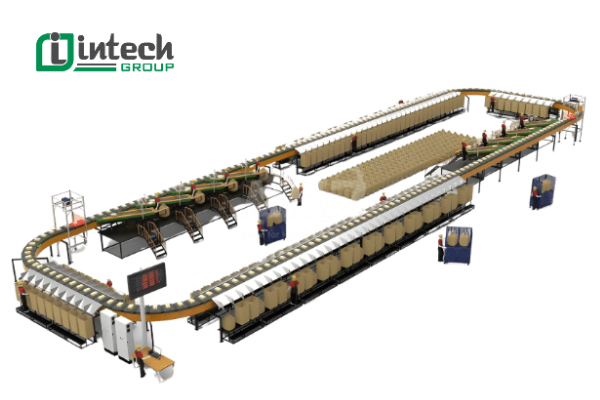

Product transport conveyor

Is the central part that helps move products through measuring and sorting positions. Intech Group designs and manufactures all kinds of industrial conveyors, cargo conveyors, component assembly conveyors, chain conveyors, PVC conveyors, roller conveyors, ... with stable speed, customizable according to production needs. The conveyor materials selected by Intech Group ensure high durability, smooth operation and suitability for each specific product type.

Height measuring sensor (Sensor/3D Camera)

Depending on the requirements, the system can use laser sensors, optical sensors (Photoelectric Sensor) or 3D cameras to scan data. This data will be sent to the central controller for processing and classification decision making.

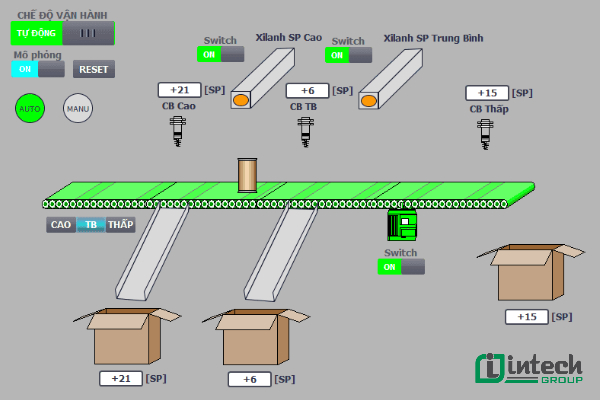

Central controller (PLC, HMI)

The PLC central controller receives signals from the sensor, compares them with the set standard values, and then transmits commands to the classification mechanisms. The HMI screen helps the operator easily monitor, adjust parameters, and monitor the system status in real time.

Classification mechanism (swiper, cylinder, robot, gripper arm)

After the data is processed, the classification mechanisms will operate to put the product in the correct corresponding position. Depending on the actual application, Intech Group can design a system using automatic wipers, pneumatic cylinders, or pick-and-drop robots, loading and unloading robot stations, sorting conveyors, and industrial robots to ensure high speed and accuracy.

Data display and monitoring system

Monitoring software allows users to monitor system performance, count the number of qualified and unqualified products, and store data for traceability, helping businesses easily manage, evaluate and optimize production line productivity.

Operating principle of the height product sorting system

The height product sorting system operates based on the mechanism of automatically identifying, measuring and classifying products through sensors and central controllers. The basic operating process includes the following steps:

- Receiving and moving products: Products are placed on the conveyor belt and moved evenly through the measuring area.

- Measuring and collecting height data: Sensors or 3D cameras will measure the height of each product when passing through, collect data and send signals to the central controller (PLC).

- Processing and comparing data: PLC analyzes and compares measured parameters with the set standard values, thereby determining whether the product meets or fails to meet the height standards.

- Automatic sorting: After processing, the PLC transmits commands to the sorting mechanism such as the wiper blade, pneumatic cylinder or gripper robot to put the product in the correct corresponding position.

- Display and monitoring: All classification results are displayed visually on the HMI screen, and data is stored for inspection, evaluation and production optimization.

Advantages of using a height-based product sorting system

The application of a height-based product sorting system in the production line brings many practical benefits to businesses, especially in the context of increasingly strong automation.

Increasing accuracy in inspection and sorting

The system uses sensors and cameras to measure height with high accuracy, helping to quickly detect products with size deviations, ensuring consistent output quality. Eliminating manual errors helps businesses minimize errors and the rate of returned goods.

Optimizing productivity and production speed

With the ability to operate continuously, the automatic sorting system helps increase product processing speed, meeting the needs of large-scale production while still ensuring stability. The system can work 24/7 without depending on human factors.

Save labor and operating costs

Thanks to fully automated operation, businesses can significantly reduce labor costs for inspection and classification stages. At the same time, optimizing the process helps save time and improve resource efficiency.

Easy integration into existing production lines

The height product sorting system provided by Intech Group has a flexible design, easily connected to conveyors, robots or production management software (MES, ERP). This helps businesses expand automation without having to change the entire line.

Improve data management and retrieval efficiency

All information about products, height parameters, and classification results are stored and displayed visually on the monitoring system. Businesses can easily monitor performance, retrieve data, and make quick and accurate management decisions.

Applications of height-based product sorting systems in manufacturing

The height-based product sorting system is widely used in many industries thanks to its high automation and outstanding flexibility.

- In the food and beverage industry, it helps to sort bottles, cans, and boxes by height to ensure accurate packaging.

- In the electronics and components industry, it is used to sort products by size for automatic inspection or packaging.

- In plastic, pharmaceutical, and logistics factories, product sorting systems are applied to increase productivity, reduce manual errors, and ensure consistent product quality.

Notes when choosing a product sorting system by height

- Each type of product has different sizes, shapes and materials, so it is necessary to choose the appropriate sensor system and sorting mechanism to achieve the highest accuracy.

- Production line speed: The system needs to be synchronized with the existing conveyor speed to ensure the sorting process is continuous, without causing congestion or production interruptions.

- When integrated into an automatic line, the system needs to be compatible with PLC, pick-and-place robots or smart conveyors to ensure synchronous operation and optimize the entire process.

- Choosing a reputable supplier like Intech Group helps businesses feel secure about the quality of the equipment, 24/7 technical support and periodic maintenance, ensuring the system always operates durably and effectively in the long term.

Intech Group's height sorting system solution

Intech Group provides height sorting systems designed and manufactured according to industrial standards, meeting the automation needs in many different manufacturing fields. Intech's solutions not only help businesses increase processing speed, reduce manual errors, but also improve accuracy and operational efficiency across the entire chain.

With a team of experienced engineers, Intech Group is committed to providing comprehensive automation solutions, including consulting, design, integration and after-sales maintenance. Each system is customized according to the production characteristics of each enterprise, helping to optimize productivity, reduce operating costs and increase competitiveness.

Contact Intech Group immediately via Hotline: 0966.966.032 - 0983.113.387 for advice on smart sorting automation solutions, accompanying businesses on the journey of digital transformation of modern manufacturing plants.