Mục lục

To effectively invest in Logistics services, it is necessary to have a good and overall strategic thinking, but need to focus on investment, so what is the secret to helping businesses break through?An automated parcel sorting system will bring a big transformation in the logistics supply chain.Applying parcel classification system to our Logistics service chain, we will create a breakthrough and difference for our services.

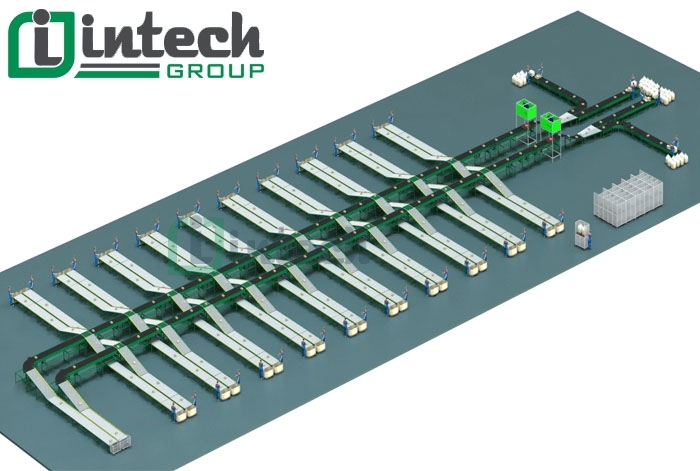

VERTICAL CROSSBELT SORTING SYSTEM ( IT - SS - VCB )

VERTICAL CROSSBELT SORTING SYSTEM ( IT - SS - VCB )

- High-speed sorting capacity up to 10,000 products/hour, the system can operate continuously;

- The highlight of the vertical crossbelt sorting system is that it saves space.Only 2.5 m wide space is enough to install this type of crossbelt sorting system.

- Like the horizontal crossbelt system, this vertical crossbelt system consists of a series of crosbelt carts distributed in a 90 degree direction along the vertical circle of the grading system.

- Before the goods go to the sorting station, they are stored on previous conveyors and the conveyors are all conventional conveyors.

- The outlet addresses are configured through the selector software system, which makes changing the feeder address more flexible with each specific selection condition.

- Low noise makes working conditions more pleasant and comfortable.

- The rate of misclassification of parcels is as low as 0.01% which makes your service superior and different.

- The rate of damaged, broken and dented goods will be reduced thereby improving service.

Features:

- The highlight of the Vertical Crossbelt sorting system is that it saves space.Only a compact space with a width of 2.5m is enough to install a Vertical Crossbelt sorting system.

- Like the Horizontal Crossbelt system, this Vertical Crossbelt system consists of a series of Crossbelts distributed 90 degrees in the vertical circle of the system above the ground.

- Sorting technology that does not change the orientation of the product during transit ensures safe sorting of even the lightest and most fragile products.

- The outlet addresses are configured through the splitter software system, making it more flexible to change the address on the outputs to each desired split condition.

- Low noise makes working conditions and environment of workers more friendly.

Intech is one of the leading technology companies in Vietnam developing a product sorting system based on Crossbelt Sorter, Wave sorter or Pop-up technology. The systems are applied IoT connection technology to operate, check, monitor and manage data remotely. The data is stored on the server automatically in real time, which can be automatically analyzed and compared to give automatic warnings about the status of goods.

The automated parcel sorting system is widely applied in courier (CEP) and e-commerce enterprises and in smart warehouses.

See more:

- Pop-Up classification system

- Wave-Sorter sorting system

Products of the same category

-

Pop-Up sorting system

Designed for moving and sorting large packages and weighing up to 35kg with independent operation, stability, energy saving, and low maintenance costs;

-

Wave-Sorter sorting system

The Wave-sorter sorting system is a very popular module nowadays, widely applied in the commodity classification industry, it has the ability to classify up to 10,000 products/hour.

-

Cross belt - Sorter sorting system

Cross belt - Sortersorting system is a very popular module today, widely used in the goods sorting industry, with the ability to sort at high speed up to 25,000 products/hour.