What is Andon? The Role of Andon System in Production

18-10-2025 27

The Andon system originated in Japan, a country famous for its continuous improvement standards in manufacturing. Initially, Andon was successfully developed by Toyota and later became a popular method globally.

So what is the Andon system and what is its role in production? Let's find out through the article below:

What is the Andon system?

The Andon system is a tool that helps identify and notify abnormalities that arise during the production process. When there is a problem, the system will immediately send a warning signal through sound and image, sent to the group of personnel in charge of the problem area.

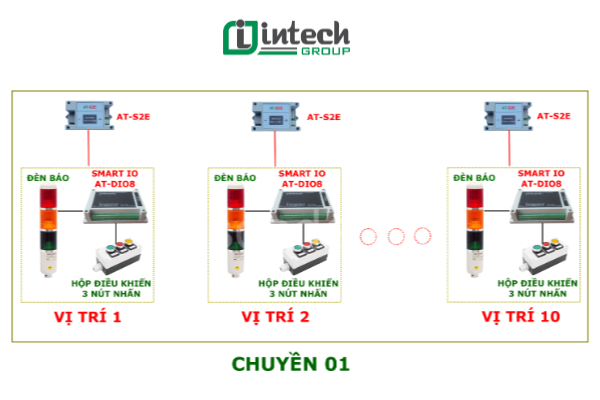

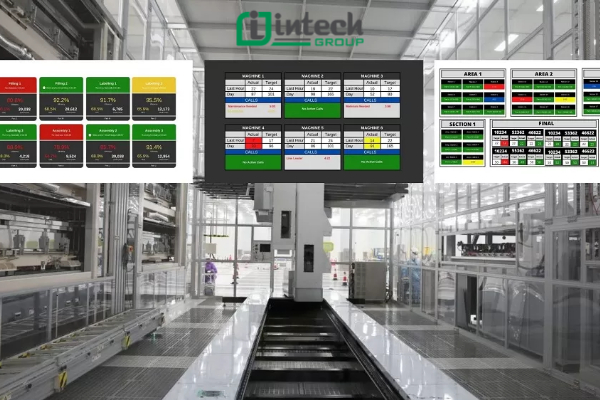

The Andon system can be present in many forms: from warning at a specific location, such as a production machine, to warning on many lines and stages. Warnings can be simple, just lights or bells, or more complex with electronic notice boards. The common point of these types of warnings is to provide real-time information about the production status in the monitored area, helping businesses easily monitor and handle promptly when problems occur.

The Role of Andon Systems in Manufacturing

Andon systems play a vital role in optimizing and controlling the manufacturing process. Here are the specific roles of Andon in the factory:

Instant warning when problems arise in production

Andon helps to immediately detect problems, from minor to serious, and immediately notify the team in charge via audio or visual signals, allowing timely handling.

Simple and consistent communication on the production floor

The Andon system is a clear and consistent communication channel, helping to quickly convey production information to all personnel on the floor. As a result, incidents or unusual situations are constantly updated, making it easier for everyone to grasp the situation.

Encourages immediate response to incidents

Andon promotes rapid response to quality, machine or safety issues, minimizing extended production downtime and improving process reliability.

Increases operator accountability and empowerment

Supports quick problem resolution by monitoring

Andon benefits in management and production

Preventing defective products: Andon helps prevent defective products before they reach customers and avoids mass production failures.

Save time troubleshooting: When an incident occurs, the system will clearly indicate the area and problem that needs to be resolved, helping the support team get to the right place and reduce the time to fix it.

Why should Andon be applied in production?

Andon System Operation Principle and Classification

Andon System Operation Principle

Andon System Classification

Andon systems are designed in a variety of ways to suit different production needs:

- Location or line warnings: Andon can issue warnings at a specific location or on multiple lines or stages.

- Simple and complex warnings: Warnings can be displayed simply by lights or bells, or through complex electronic boards.

All types of Andon systems have in common the provision of real-time warning information about the production status in the monitored area.

Notes when using the Andon system?

- Andon systems are capable of warning when problems arise but do not automatically handle those errors; intervention by specialized staff is required.

- Andon cannot completely eliminate errors on the line or product. If the problem is not handled, the system will continue to warn and may stop the line in subsequent operations.

- Although it can notify fault status or line operation, Andon should not be used as a human-to-human communication tool. For communication, workers and supervisors still need to contact directly.

- The Andon system does not guarantee that the product will meet the customer's requirements if the factory's definition of quality standards is not consistent with the customer's requirements.

Which production models should the Andon system be applied to?

Applying technology to production today is an important factor to help optimize the efficiency of lean production. The Andon system supports automation in monitoring and warning, helping:

- Minimize machine and worker downtime.

- Timely updates on product quality status.

- Optimize productivity, minimize defective products, inventory and waste.

The Andon system is suitable for production lines and factories with highly decentralized workflows, helping to maintain efficiency and production quality according to lean standards.

Conclusion

Hopefully, with the useful information provided by Intech Group in the article, it will help you understand the Andon System. If your business is looking for an Andon system solution or an effective production management system to increase factory efficiency, please contact Hotline 0966.966.032 - 0986.448.456 for support and advice from our team of experienced experts.

Reference: