SHUTTLE PALLET WAREHOUSE - SHUTTLE PALLET SYSTEM - WIRELESS PALLET SHUTTLE SYSTEM

In this context, there is a need to focus more on designing and implementing more flexible and versatile warehouses that can meet the three most important needs of today's market: High storage density, low storage costs, fast in-out times. Intech, paying attention to the changes in the business market, has chosen to develop high-density systems to support companies to meet these needs flexibly. In particular, the Pallet Shuttle Automated Warehouse System is a very cost-effective warehouse automation solution, but it is very effective, especially useful in compact warehouses with consumer products, cold storage environments, warehouses with a large number of pallets per SKU.

I. OVERVIEW OF PALLET SHUTTLE - MODERN WAREHOUSE SYSTEM

In order to help customers understand the outstanding features of the high-density semi-automatic warehouse system, Intech Group introduces the Pallet Shuttle automatic warehouse system to you with the most outstanding information about the warehouse system below.

1. What is Pallet Shuttle?

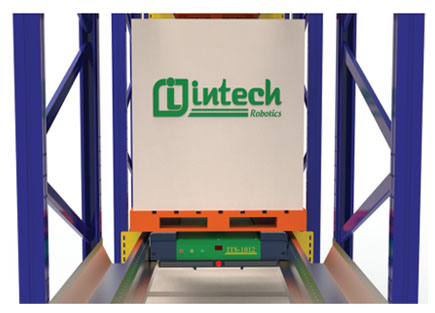

Intech Pallet Shuttle is a modern system, researched, developed, completed and supplied to the market by us in 2022. Robot Shuttle is a line of loading and unloading machines in warehouse shelves, an important part of the Pallet Shuttle warehouse system that helps to transport goods in shelves in the most optimal way. This is a line of robots running on rails, storage lanes to load and unload pallets in warehouse shelves, through a system of forklifts - robots that are programmed and scientifically controlled.

2. What is Pallet Shuttle Warehouse?

Pallet shuttle warehouse is a semi-automated storage solution or High-density automated storage system, which uses a shuttle vehicle running along rails on racks to import and export pallets. This helps increase the number of pallets stored and improve the time of loading and unloading pallets in the warehouse. Logistics has become an important factor in business management, as it allows to create real competitive advantages.

Video of operation of pallet shuttle warehouse

II. PALLET SHUTTLE WAREHOUSE OPERATION PROCESS

In the Pallet Shuttle Radio semi-automatic warehouse system, forklifts will place pallets on the rails at the beginning of each lane. The vehicle will lift and move the pallets to the nearest empty position in the lane, maximizing storage space. The movement of the Shuttle vehicles inside the rack is automatic, following the operator's command via the control handle.

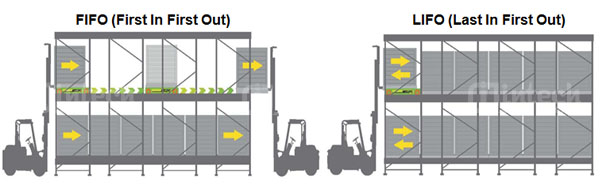

- FIFO (first-in, first-out): the first pallet stored on each racking lane will be the first pallet unloaded from that lane. Forklifts will operate on 2 sides of the warehouse: 1 side for storage, 1 side for unloading. Suitable when the warehouse is arranged as a buffer zone between 2 areas.

- LIFO (last in, first out): the last pallet stored on each racking lane will be the first pallet unloaded from that lane. Loading and unloading is done on the same side of the warehouse. This is the most common method used at Shuttle Radio warehouse.

|  |

| Step 1: The forklift lifts the shuttle onto the shelf lane that needs to store or export pallets. | Step 2: Next, the forklift moves the pallet to the storage lane. The forklift never enters the rack. |

|  |

| Step 3: The operator uses the remote to send commands to the Shuttle. Once the pallet's position has been determined, the shuttle will lift the pallet and move along the depth of the rack to the nearest pallet, then lower the pallet. | Step 4: The shuttle returns to the front of the racking lane to store the next pallet (if needed) until the racking lane is full. To export pallets, the operator performs the same operation. |

Functions that the Shuttle Radio warehouse system can perform:

| Standard | Advanced | ||||||

| Storage: Stack each pallet on the rack | Pallet stacking: automatically stacks pallets to make room (FIFO function - stacking goods for storage) | ||||||

| Export: Take each pallet to the end of the shelf | Pallet consolidation: automatically consolidates pallets to make free space (FIFO function - consolidates goods for shipping) | ||||||

| Continuous unloading: Take the pallet to the end of the shelf, while waiting for the forklift to take the pallet, continue to run in and take out another pallet. | Waiting for unloading: take the first pallet and run to the front of the shelf, then go back and continue to take the second pallet. If the first pallet has not been taken by the front of the shelf, wait until the first pallet is taken and automatically place the second pallet in the position of the first pallet. | ||||||

| Set the distance between pallets from 20-150mm | Prevent collision between shuttles on the same shelf lane. | ||||||

| Remote can control 4 devices at the same time | Count the number of pallets in stock |

III. STRUCTURE OF PALLET SHUTTLE ROBOT WAREHOUSE

1. Overview of shuttle robots

- What is Robot Shuttle?

Shuttle robots are automated devices designed to move specific goods or materials in areas such as logistics, warehousing, and manufacturing facilities. Robots can move along fixed or flexible routes depending on the design and technology used.

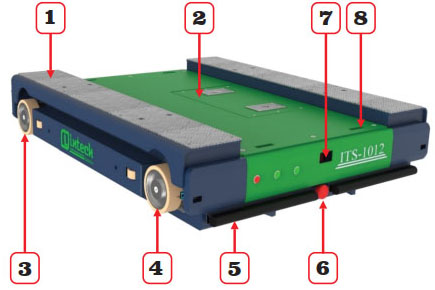

- Shuttle robot structure:

Shuttle robots are designed with high speed, equipped with various safety devices with the following structure:

1. Pallet lifting and lowering cluster

2. Lithium battery cluster

3. Guide wheel cluster

4. Drive wheel cluster

5. Safety sensor

6. Emergency stop button

7. Distance sensor

8. Pallet check sensor

Technology used for Robot Shuttle is often equipped with technologies such as laser guidance systems, sensors, management software to navigate and optimize the movement process. These technologies allow them to operate efficiently and safely in different working environments.

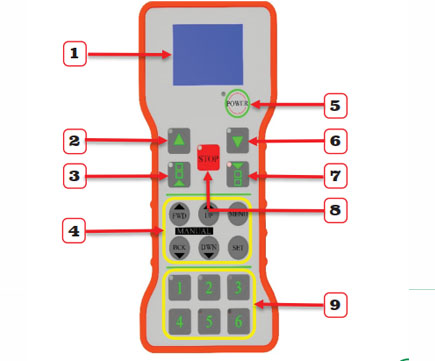

Controller structure:

The controller is designed with function keys that are easy to operate.1. Display screen

2. Single item input button

3. Continuous item input button

4. Manual button cluster

5. Power on/off button

6. Single item output button

7. Continuous item output button

8. Stop button

9. Vehicle selection button cluster

Full structure of pallet shuttle warehouse?

1. Shelf frame

Pallet racks, also known as storage racks, are items used to lift, support, and store goods in the warehouse. Shelf frames come in a variety of types to meet the load capacity, style, and size of products in the warehouse to suit all industries.Now when mentioning shelf frames, we cannot help but mention pallets on the frame:

-

Plastic pallets: They are often made from recycled or new plastic, have high load-bearing capacity, are durable, do not rot, and are not harmful to the environment. Plastic pallets are widely used in industries, warehouses, supermarkets, and logistics systems, ... can be reused many times and are easy to clean. This helps to minimize transportation and maintenance costs, while reducing the impact on the environment.

-

Wooden pallets: Widely used in warehouse shelving systems to store goods due to their affordable price, unlimited distribution quantity according to orders, solid structure, and ease of use.

-

Iron pallets: They are made from iron or steel, have high load-bearing capacity and are suitable for storing heavy goods but are rarely used due to their high cost. In addition, the iron material often makes the shelves heavy and easy to oxidize if not properly stored.

2. Forklift

Forklift is a device for transporting and lifting goods widely used in warehouses, warehouses, ports and manufacturing facilities. Forklift is designed to lift, move and stack goods efficiently and save time.

Forklift in smart warehouse

3. Robot Shuttle AGV - Automatic Picking Vehicle

Robot Shuttle AGV (Automated Guided Vehicle) is a type of automatic picking vehicle used in automation systems in warehouses and factories. Shuttle Robots are designed to automatically move, pick up and transport goods from one point to another on pre-designed shelves, programmed from a remote control system.

Automatic Picking Vehicle - Robot Shuttle AGV in smart warehouse

This is a line of automatic picking robots, AGV Robots are really effective in pallet shuttle warehouses for the manufacturing industry, smart warehouses bring benefits to businesses compared to other current warehouse models.

IV. ADVANTAGES AND DISADVANTAGES OF SHUTTLE RADIO WAREHOUSE

1. Advantages of the warehouse

The shuttle warehouse is an automated system in warehouse management and operation, including:

a. Space optimization: The depth of the warehouse can be up to more than 40m

-

The system optimizes the distance between floors to optimize the storage space

-

Through the use of pallet distance check sensors, the Shuttle can stack pallets close together according to a set distance parameter, helping to eliminate maximum empty space in the warehouse.

b. Cost savings: The Shuttle Radio warehouse helps reduce short-term costs.

- Space optimization helps reduce warehouse space costs

- Lower energy consumption, especially in cold storage due to minimizing the space that needs to be cooled.

- The forklift does not have to go into the shelf lanes, minimizing the risk of collision with shelves, reducing shelf maintenance and repair costs.

c. Save time: Reduce loading and unloading time because the forklift does not need to go inside the shelf lane

-

The Shuttle's moving speed reaches 75 m/min when empty and 35 m/min when loaded.

-

The loading speed is only 1.5s

-

The robot is equipped with continuous loading and unloading features, assembling goods to save maximum time.

d. Increase productivity: The Shuttle imports and exports goods in the rail, reducing the work for the forklift

-

Fast import and export time helps increase the volume of stored goods.

-

The system operates stably, is easy to use and maintain

-

Includes inventory management function to help retrieve goods quickly, minimizing labor.

e. Flexibility: SKUs will be grouped by lane to help store more types of goods.

-

Any type of forklift can be used.

-

Can work with pallets of different sizes

-

Easily expandable when you want to increase the storage capacity of the warehouse

-

Can operate in both LIFO and FIFO modes

f. Safety: Because the operating principle of the Shuttle Radio warehouse is that the forklift does not go inside the shelves, the risk of an accident is almost non-existent

2. Disadvantages of shuttle warehouse investment

-

High initial investment cost: To deploy the Pallet Shuttle system, businesses need to invest a large amount of money in equipment, software and installation. In addition to the warehouse racking system, another heavy cost is the shuttle robots on each rack rail. This can become an obstacle for small businesses or businesses with limited financial resources.

-

Dependent on technology: The deployment of this smart warehouse system is completely based on technology and software for control. If a problem or technical error occurs, it can lead to disruption of operations and affect the efficiency of the warehouse.

-

Requires professional training and maintenance: As with modern warehouse models in the goods storage market, training of staff needs special attention. To operate and maintain the Pallet Shuttle system effectively requires professional human resources and high training costs.

-

Product type limitations: For optimal warehouse operations, it is recommended to use in warehouses with products packaged on pallets and of standard sizes. For products that are not uniform or have special sizes, this system may not be suitable.

-

Long implementation time: The installation and implementation of the Pallet Shuttle system can take a long time, from several months to a year, depending on the size and complexity of the project. This can cause disruptions to warehouse operations during the implementation period.

Both the racks and the Shuttle are equipped with safety devices to help the system operate well, protecting the operator and the goods

The pallet shuttle warehouse brings many significant benefits to warehouse management and operation, from optimizing space and increasing productivity to minimizing errors and increasing business flexibility. Customers who need to improve their warehouse can refer to the types of smart warehouses Intech provides in the Both the racks and the Shuttle are equipped with safety devices to help the system operate well, protecting the operator and the goods

The pallet shuttle warehouse brings many significant benefits to warehouse management and operation, from optimizing space and increasing productivity to minimizing errors and increasing business flexibility. Customers who need to improve their warehouse can refer to the types of smart warehouses Intech provides in the Smart Warehouse section.