Learn about lithium battery production line

11-09-2025 41

Lithium battery production lines are becoming the focus of the clean energy technology race, especially in the field of electric car and electronic device manufacturing. With large energy storage capacity, high efficiency and fast charging time, Lithium-ion has opened a new era for the global industry.

To meet the growing demand, modern battery factories are investing heavily in automating and optimizing every step in the production line, from material preparation, electrode coating, battery assembly pressing to output quality testing. Intech Group will help you learn in detail about the process, technology and key factors that make up an international standard lithium battery production line.

History of Lithium Battery Manufacturing

Lithium-ion (Li-ion) batteries are one of the most important inventions of the 20th century, contributing to completely changing the mobile energy industry and modern electricity storage technology. With a structure consisting of two electrodes and an electrolyte solution containing LiPF₆ salt, this type of battery operates based on the mechanism of exchanging Li ions between the cathode and the anode during the charging and discharging process. This simple but effective design has helped Li-ion batteries become the priority choice for the world's leading electric vehicle manufacturers.

In 1970, Lithium batteries began to develop when British chemist M. Stanley Whittingham first used titanium sulfide and lithium metal to make electrodes. Despite the great potential benefits, lithium batteries could not be mass produced at that time due to high costs and the risk of producing toxic gases such as hydrogen sulfide (H₂S) when exposed to air. By 1980, Professor John Goodenough had upgraded the electrode material with lithium cobalt oxide, which significantly improved stability and performance. In 1983, Japanese scientist Akira Yoshino continued to optimize this technology to create a safer, more efficient battery prototype, laying the foundation for modern Lithium-ion batteries.

The year 1991 was the most important milestone when the first lithium battery production line was successfully deployed on an industrial scale by Sony Energytec. With the launch of Li-ion batteries in various shapes, from cylindrical to flat, the manufacturing industry officially entered a new era where the lithium battery production line is not only a technology, but also a core element to create battery products with high performance, long life and optimal safety.

Today, from electronic devices to electric cars, the presence of lithium batteries stems from a strictly controlled production chain and advanced automation applications to ensure quality and sustainability.

What is a Lithium Battery? Practical Applications

Lithium batteries, especially lithium-ion (Li-ion) batteries, are advanced rechargeable batteries that use lithium ions as the main component to store and release energy. During charging, Li ions move from the positive electrode to the negative electrode and vice versa during discharging. Thanks to its efficient operating mechanism, compact size, fast charging capability and environmental friendliness, this type of battery is increasingly widely used in life and industry.

Currently, lithium batteries are commonly found in consumer electronics such as smartphones, vacuum cleaners, laptops, laser pointers, air purifiers. In particular, with the green transition trend in transportation and energy, lithium batteries are also the main energy source for electric vehicles (EVs), electric cars, AGVs, loading and unmanned aerial vehicles, as well as power storage systems in the aviation and defense industries.

To meet the needs of large-scale production and ensure quality, lithium battery production lines have been highly automated by factories with modern technology. Each process from material preparation, powder mixing, electrode coating, cell assembly, charging, shaping to packaging and testing requires absolute precision to create battery products that meet international standards. Thanks to the development of this line, lithium batteries not only meet the needs of performance but also ensure durability, safety and environmental friendliness in all practical applications.

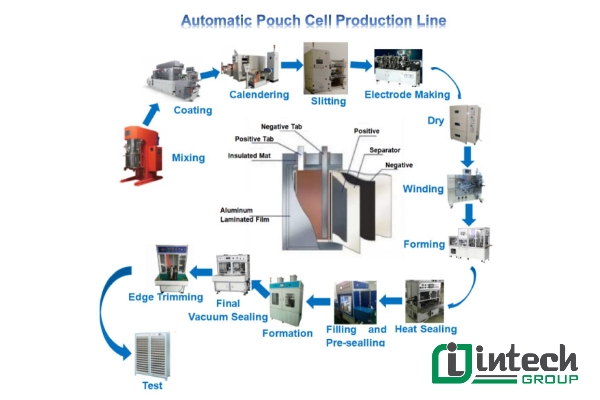

What is the Lithium battery production process?

In the context of the increasingly clear trend of switching to green energy, the lithium battery production line plays a key role in meeting the demand for batteries for electric vehicles, electronic devices and energy storage. Lithium batteries have a general structure including: anode, cathode, electrolyte and diaphragm. Here is the Lithium battery production process you need to know:

Step 1: Prepare the electrode

Input materials such as active agents, conductors and binders are mixed together to form a homogeneous slurry. This mixture is coated on aluminum foil (positive electrode) and copper foil (negative electrode), then dried using specialized equipment.

Using water as a solvent is a major advantage in the environmentally friendly clean energy production line. After drying, the electrodes are put into a vacuum oven to remove excess moisture, helping to prevent corrosion and increase battery life.

Step 2: Assembling the battery cell

The electrode layers are rolled or stacked with a diaphragm to form the cell structure. Next, the positive and negative electrodes are welded using ultrasonic or resistance technology.

After the cell is placed in the case, liquid electrolyte is pumped in and then sealed. Depending on the manufacturer, the cell case design may vary. This is a stage that requires absolute precision and good control to prevent leakage or loss of safety.

Step 3: Electrochemical activation

This stage creates the SEI (Solid Electrolyte Interphase) layer, a solid electrolyte interface layer, which helps protect the anode, preventing short circuits or explosions. The battery cells will undergo a charge/discharge cycle at a low rate (C/20) and then gradually increase, then be stored in a special environment to stabilize the SEI layer.

Finally, degassing is to remove the gas generated during the electrochemical process, helping to complete the battery cells before mass packaging. The time for degassing and aging the battery can last from a few days to a few weeks depending on the technological process.

Currently, many factories in Vietnam are also applying the above process to build lithium battery production lines for the electric car and industrial equipment industry. In particular, integrating smart transportation technology such as AGV self-driving vehicles helps optimize production efficiency, reduce labor, optimize operations, and ensure safety in production.

The Future of Lithium Battery Technology and Production Lines

In the context of the global move towards clean and sustainable energy, lithium battery production lines are being heavily invested in to meet the growing demand from fields such as electronics, transportation, healthcare, military, and aerospace. Today's lithium battery production technology does not only stop at performance and safety, but also aims to optimize costs, increase energy density, extend life and minimize environmental impact.

To realize these goals, researchers around the world are continuously developing new generations of batteries such as Lithium-Sulfur (Li-S) batteries, Sodium-ion (Na-ion) batteries, Magnesium batteries and advanced materials such as Lithium Cobalt Oxide, Lithium Titanate, etc. However, despite their great potential, these battery lines are still in the testing phase and cannot be mass-commercialized like Li-ion batteries. To overcome this barrier, not only the materials but also the processes in the lithium battery production line need breakthrough improvements, ensuring the ability to transition from laboratory research to efficient mass production.

In the near future, lithium battery production lines are also expected to play an important role in storing renewable energy such as solar and wind power, thereby contributing to reducing CO₂ emissions and protecting the environment. Notable trends include replacing toxic liquid solvents with solid electrolyte materials such as polymers, ceramics or glass, helping to improve the safety and environmental friendliness of Li-ion batteries.

From this, it can be seen that technological innovation and upgrading of lithium battery production lines are not only technical advances, but also a long-term strategy for sustainable development in the future energy industry.