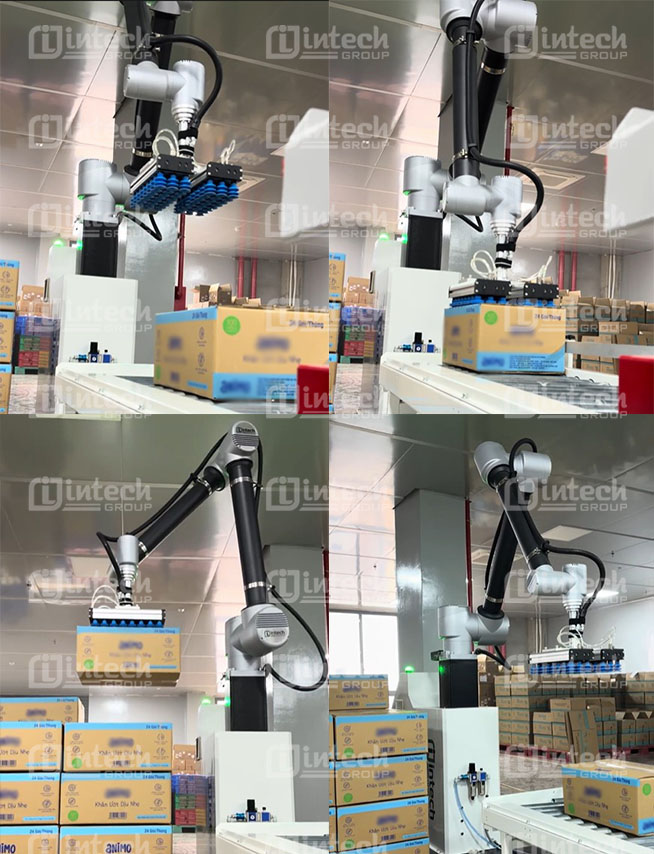

Robotic loading and unloading station solutions for the consumer goods manufacturing industry.

10-01-2026 27

Robotic loading and unloading station solutions for the consumer goods manufacturing industry automate the final stage of production, enabling fast, accurate, and stable stacking of wet wipes boxes onto pallets.

Features & Specifications of Robotic Loading and Unloading Station for Consumer Goods Manufacturing:

Integrated system of high-capacity collaborative robots with advanced mechanical and control modules, ready for flexible deployment in various factory models.

Heavy-Duty Collaborative Robots – International Industry Standards

The station utilizes world-leading heavy-duty collaborative robots (Cobots), meeting international safety and performance standards.

- Robust mechanical structure, high rigidity

- Stable handling of large packages, cartons, and product packaging

- Optimal working speed while ensuring safety when operating near humans

Mobile Platform – Flexibility in Line Layout

|

| Báo giá Trạm robot bốc xếp |

- Quotation for Robot Loading and Unloading Station

- Easily move the robot station between production locations

- Quickly reconfigure when changing factory layouts

Suitable for both new factories and renovated/upgraded production lines

This design helps businesses optimize space while improving adaptability to changes in production volume and product types.

Seventh Axis Lifting Column – Expanding Workspace

The integrated seventh axis (Vertical Axis) lifting column is a key technical highlight, enabling the robot to:

- Move vertically smoothly and precisely

- Significantly expand the working area along the pallet height

- Flexibly accommodate various pallet stacking configurations

As a result, the robot station can efficiently handle multi-layered pallets of varying heights – especially common in the FMCG industry.

Vacuum Head – Lightweight, Durable, and High-Performance

The robot station is equipped with a specialized vacuum head, optimally designed for various types of cardboard boxes, packaging bags, soft packaging, or flat surfaces, minimizing deformation or damage to the packaging.

- Lightweight construction reduces load on the robot arm.

- Simple design, easy to maintain.

- Ensures stable grip throughout the loading and unloading cycle.

Patented Strong Suction & Anti-Drop Technology

- Maintains stable suction even on uneven packaging surfaces

- Minimizes the risk of product drop during high-speed transport

- Ensures safety when handling a wide variety of consumer goo

Tag tracking system – Accurate and efficient

The robotic station is integrated with a Tag Positioning System, which helps to:

- Accrately determine the position of pallets and product placement points

- Reduce errors during stacking

- Increase the repeatability and accuracy of each loading and unloading cycle

This system improves pallet stacking quality, ensuring uniformity and aesthetics of the goods.

Mechanical tag positioning system – Simple and reliable

- Easy to use, quick operation

- High durability, less dependent on the environment

- Increased stability in long-term operation

Benefits of using robotic palletizing stations in wet wipe production lines.

Robotic palletizing stations are an automation solution for the final stage of the wet wipe packaging line, helping businesses optimize productivity, control stacking quality, and improve operational safety. The application of robots in stacking wet wipe boxes not only replaces manual labor but also creates a foundation for flexible, modern, and sustainable production.

1. Simple Programming – Easy to Access and Deploy Quickly

The robotic palletizing system is equipped with an intuitive programming interface (visual programming), allowing for quick setup of stacking patterns without requiring personnel to be proficient in complex programming languages.

Easy to operate for ordinary technical staff:

- Setting up pallet stacking patterns

- Changing box size and number of stacking layers

- Adjusting stacking order according to each order

This helps shorten training time, reduce reliance on robot programming experts, and increase factory autonomy.

2. Easy to Operate – Flexible Adjustments During Production

The robotic station supports multiple user-friendly operating modes, allowing direct adjustments on the teaching pendant control panel or via wired/remote control.

The carton/box stacking method is optimized for:

- Simple operation

- Easy to learn and remember

- Suitable for wet wipe production environments with various packaging specifications

Therefore, changing pallet configurations is quick and does not interrupt the production line.

3. Safety and Stability – Meeting High Industrial Standards

The system incorporates highly reliable industrial force sensors, combined with a multi-level collision detection mechanism (up to 10 levels), ensuring maximum safety for operators and equipment.

- In addition, the robotic station also:

- Equipped with comprehensive safety detection sensors

Provides 16 safe I/O interfaces, maintaining full protection functions even in the event of a single incident during pallet stacking

This is especially important in wet wipes manufacturing plants – where continuous, stable operation and strict adherence to safety standards are required.

4. Flexible Deployment – Optimized Factory Space

The robotic pallet stacking station boasts an integrated, compact design, occupying less installation space compared to traditional pallet stacking systems.

Key advantages include:

- Easy placement at the end of the packaging line

- Fast construction and installation

- Simple new task setup, saving time on commissioning

A particularly suitable solution for wet wipe factories with limited space or those needing to renovate or upgrade existing production lines.

5. Flexible Production – Ready for Multiple Packaging Scenarios

Robotic stations allow for rapid switching between various packaging scenarios, flexibly meeting diverse order specifications and production volumes.

Supporting systems:

- Safe human-machine collaboration

- Synchronous connection with carton folding and sealing machines and film wrapping machines

- Operation of multiple robots simultaneously in the same production line

- Automated production line - transporting goods to various stages in the production line

- AGV or AMR robots in the factory (if the production line is digitized in the future)

As a result, wet wipes factories can improve their adaptability to the market, optimize efficiency, and move towards a smart, flexible, and sustainable production model.

| Manufacturing Automation Solutions & Robotics Solutions |