What is Cavity? How to calculate Cavity?

18-10-2025 23

Cavity is an important term in the modern manufacturing industry, especially in plastic injection molding. Understanding Cavity helps businesses optimize the number of mold cavities, thereby minimizing production costs and increasing business efficiency.

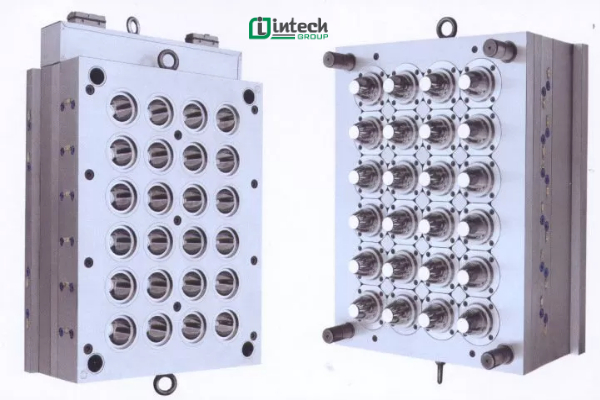

What is Cavity?

In the field of plastic manufacturing, Cavity is the number of cores or cavities in a plastic injection mold set. Cavity directly affects the number of products produced in an injection molding cycle. Each mold set usually consists of two main parts:

- Cavity (Female mold): This is the fixed mold part, mounted on the fixed plate of the plastic injection machine.

- Core (Male mold): This is the movable mold part, mounted on the movable plate of the plastic injection machine.

Cavity Calculation Formula

Here are some ways to calculate the number of mold cavities depending on the characteristics of the press as well as the product requirements:

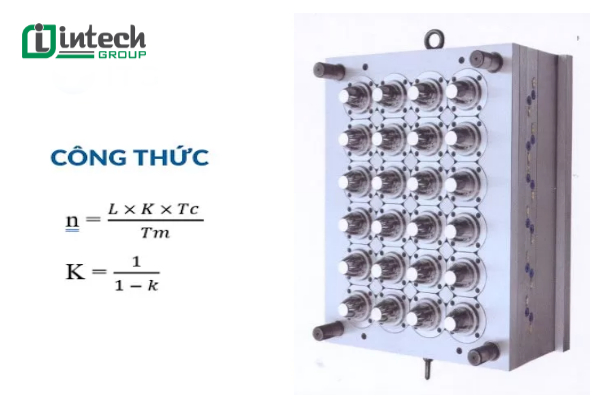

Calculate by the number of product batches

This is a calculation method that does not include the effects of the machine. This method allows to estimate the delivery time of the product.

Cavity Calculation Formula - Calculated by the number of product batches

In which:

-

n : Minimum number of molds

-

L : Number of products per production batch

-

K : Scrap coefficient (%)

-

k : Scrap rate (%)

-

Tc : Injection cycle time of the product (s)

-

Tm : Time required to complete a batch of products (days)

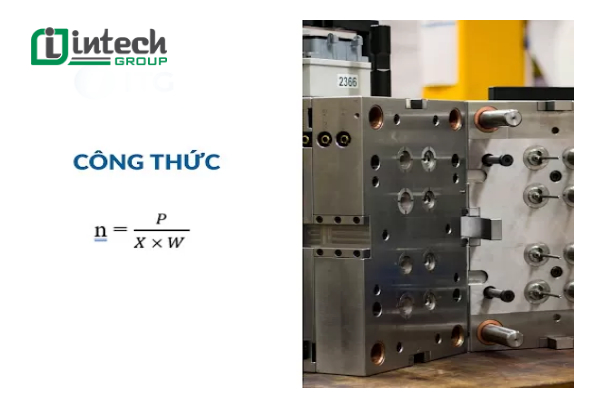

Calculated according to the plastic capacity of the machine

Cavity calculation formula - Calculated according to the plastic capacity of the machine

In which:

-

n : Maximum number of mold cavities on the mold

-

P : Plasticizing capacity of the machine

-

X : Injection frequency per minute (estimated)

-

W : Weight of the product

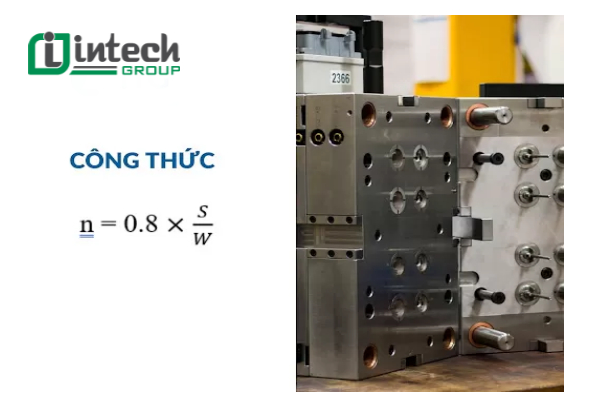

Calculated according to the injection capacity of the machine:

Cavity Calculation Formula - Calculated by the machine's injection capacity

In which:

-

n: Maximum number of mold cavities on the mold

-

S: Machine's injection capacity

-

W: Product weight

If the machine has a part with a complex shape, the business can divide that part into simple blocks and then apply the above formula.

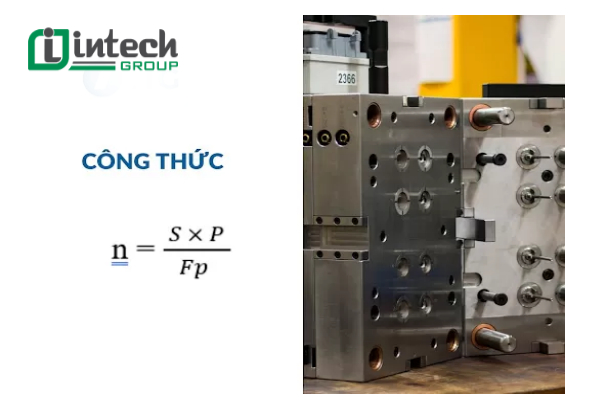

Calculated by the machine's mold clamping force

Where:

-

n : Maximum number of cavities on the mold

-

Fp : Maximum mold clamping force of the machine

-

S : Average surface area of the product in the mold closing direction

-

W : Pressure in the mold

This article focuses on calculating the size of the mounting plate on the press and the cavity cooling systems. Here are the important factors to note:

Calculating the size of the mounting plate on the press

Once the number of cavities that meet the requirements has been found, the next step is to design the preliminary size of the mold plate. During this process, the administrator needs to pay attention to:

- Mold set size: This helps ensure that the cavity fits the existing press.

- The size of the mold fixture: This is an important factor to ensure the ability to arrange the cavity reasonably.

- Adjust the number of cavities: If necessary, reduce the number of cavities or replace the press to suit the design size and production requirements.

Mold Cooling Systems

Mold cooling is essential to ensure high quality products and avoid deformation. An asynchronous cooling system can lead to uneven cooling, affecting product quality. Cooling systems include:

Series cooling system

- Characteristics:

- There is a cooling circuit in series from the inlet to the outlet.

- A clear temperature difference between the inlet and outlet.

- The temperature gradually decreases during the flow process.

Parallel cooling system

- Characteristics:

- Separate cooling circuits but with the same cooling temperature.

- The temperature difference between the inlet and outlet is small.

- The temperature is evenly distributed throughout the mold system.

Multi-stage cooling system

- Characteristics:

- Used for multi-stage molds, with similar characteristics to the parallel cooling system.

- This system allows the mold layers to cool at a uniform temperature, ensuring product consistency.

By optimizing the dimensions and cooling system, the mold manufacturing process will be more efficient, ensuring stable product quality and increasing production capacity.

Impact of the number of cavities on the cost of mold making

The number of cavities required on the mold

Cavity (mold cavity) is an important factor that directly affects the cost of mold making as well as production capacity. Below are the main aspects related to the impact of cavities:

- Increasing the number of cavities means increasing the cost of mold making: The more cavities the mold has, the higher the cost of mold making. This is because the mold size is larger, the processing time is longer and the number of mold components needed is greater.

- Mold component cost: A large number of cavities requires additional necessary components such as cooling parts, plastic conduction systems, gas conduction, etc. These costs increase the total cost of the mold.

- Processing time: The process of processing molds with many cavities will be more complicated, requiring longer production and quality control times, increasing processing costs.

Number of finished products produced

- Increased production capacity: Molds with multiple cavities will produce more finished products in the same pressing cycle. Thus, with the same time and machine capacity, the number of products produced will be much larger than molds with few or one cavity.

- Reduced production cost per unit of product: As the number of products increases, the production cost per unit of product will decrease, because the cost of operating machinery and labor is allocated to more products. This helps increase the competitiveness of businesses in providing products at lower prices.

Benefits of multi-cavity molds

Increased productivity and reduced production costs: Using multi-cavity molds helps reduce the number of machines needed and reduce labor requirements. This not only increases production efficiency but also reduces costs for human resources and machine maintenance.

In general, although increasing the number of cavities will increase the initial cost of mold making, in return it will increase productivity and reduce the cost per unit of product, bringing a great competitive advantage to the business.

Understanding and properly applying the calculation of Cavity not only helps to optimize the cost of mold production but also optimizes the cost of operating the injection molding machine, thereby helping businesses reduce costs and increase profits. To better understand how to calculate and use Cavity, please call our experts via Hotline: 0966.966.032 - 0986.448.456.

See more: