Why invest in packaging robots?

20-10-2025 18

In the context of modern production, investing in packaging robots not only helps increase productivity and reduce errors, but also enhances automation, creating a sustainable competitive advantage in the era of Industry 4.0.

At Intech Group, we understand that each production line has its own unique requirements, so investing in smart packaging robots is considered a strategic solution to help businesses optimize performance, reduce costs, and improve competitiveness in the market.

Concept and role of packaging robots

Packaging robots are automated machinery systems designed to perform product packaging steps such as picking, placing, sorting, stacking boxes, and palletizing. Instead of using manual labor, businesses can apply industrial robot arms or robot systems integrated with automatic lines, helping to optimize the performance of the entire production process.

Currently, robotic packaging can operate independently or be directly integrated into production and assembly lines, for example in the automotive, food, pharmaceutical, electronics, or logistics industries.

Packaging robots have outstanding advantages in speed, accuracy, and the ability to operate continuously 24/7. Thanks to that, businesses can easily achieve quick return on investment (ROI), improving competitiveness in the context of increasingly popular production automation.

The Importance of Packaging Robots in the Manufacturing Industry

Improve Production Speed and Productivity

Packaging robots help businesses speed up packaging, loading and unloading, and shipping products. Compared to manual processes, robots can operate continuously with high precision, significantly increasing production throughput and ensuring delivery schedules.

Reduce labor costs and optimize resources

Instead of relying on manual labor, packaging robots can operate automatically 24/7 without interruption. Businesses thus reduce labor costs, training costs, and personnel risks, while focusing resources on higher-value stages.

Improve packaging accuracy and consistency

Robotic arms are programmed with high precision, helping to package products evenly, minimizing errors and material loss. This is especially important in industries requiring strict standards such as food, pharmaceuticals, or electronics.

Streamline and automate production processes

Integrating packaging robots into production lines helps to closely link production stages, reduce waiting time and increase the overall automation of the factory. This is an important step in the transition to smart manufacturing (Smart Factory).

Bring sustainable competitive advantages

Investing in packaging robots not only brings short-term efficiency but is also a strategic step for businesses to improve their competitiveness, helping them create long-term advantages in the market.

Types of packaging robots and their applications in production

Types of robots and automation equipment are commonly used in today's production lines.

Transmission type automatic assembly machine

This is a system that uses an automatic conveyor to transport products between assembly stages. This type of machine is suitable for large-scale production lines, helping to ensure stable speed and save time moving between stations.

AC type automatic assembly machine

Using an automatic turntable to bring products to each assembly station in sequence, this device provides high precision and saves working space, especially suitable for products with a cyclic assembly process.

Flexible Assembly Machine

This is a smart machine line that can automatically adjust parameters to assemble many different types of products. With outstanding flexibility, this system is especially suitable for businesses that produce a variety of models and change products frequently.

Robotic Assembly System

Industrial robots are used to replace manual labor in complex assembly processes. Robotic arms can perform welding, screwing, gluing, or quality inspection with high speed and precision, helping businesses standardize quality and increase production efficiency.

Automatic packaging machine

As the final stage in the production line, automatic packaging machines help product packaging to be packaged evenly, quickly and accurately. When combined with robots, this system helps businesses optimize the entire process from assembly to shipment.

Benefits of investing in packaging robots in production

Investing in packaging robots not only helps businesses increase production speed, but also brings a series of practical benefits:

- Increase labor productivity 5-10 times compared to manual processes.

- Minimize errors, ensure products meet high quality standards.

- Save labor costs, optimize operating resources.

- Operate continuously 24/7 without being affected by human factors.

- Easy to program and change stages, suitable for many types of products.

- Improve labor safety, reduce the risk of injury in industrial environments.

- Increase competitiveness and professionalism for businesses in the era of smart manufacturing.

Factors to consider before investing in packaging robots

Before deciding to invest in a packaging robot system, businesses need to carefully consider many factors related to cost, operating efficiency, compatibility and flexibility of the equipment.

Analyze investment costs and long-term profits (ROI)

Return on investment (ROI) is an indicator showing the profitability of the project. To determine the exact ROI, businesses need to calculate the total investment cost (including equipment price, tax, transportation, consulting, installation and maintenance) and net profit (due to increased productivity, reduced labor, and savings on raw materials).

If ROI is positive, the investment is profitable; if negative, businesses need to reconsider the scale or investment solution.

For example, when comparing type A and type B packaging robots, businesses can calculate the expected ROI to choose the option that brings the highest efficiency in the shortest payback period.

Identifying Automation Requirements in the Packaging Process

Before investing, it is necessary to clearly analyze the packaging process of the factory to determine the necessary level of automation. Some important systems include:

- Automatic packaging machine system - undertakes closing, sealing, wrapping or stacking of products.

- Automatic measurement & inspection system - monitors weight, size, accuracy.

- Automatic material management system - helps transport products quickly, reducing operating errors.

- Production management software (MES/ERP) - supports progress tracking, product data retrieval.

- Integrated automation and industrial robot system - helps optimize the overall packaging process.

- Internal transportation system (AGV/AMR) - transports components and boxes between areas.

- Automatic tracking and reporting system helps managers monitor performance in real time.

Compatibility with existing machinery and infrastructure

Each business has its own machinery and production lines, so it is necessary to consider the compatibility of packaging robots with existing equipment to help businesses take advantage of existing facilities, avoid waste and shorten the payback period.

Flexibility and customization

One of the reasons why packaging robots have become a top investment trend is their high flexibility. Some robot lines can integrate many technologies, suitable for a variety of industries and production processes. Besides, there are also robots that are specialized for certain types of products or tasks.

Safety and compliance with production standards

Safety is always a top priority. Modern packaging robots are often designed with collision detection sensors, emergency stop systems, operator protection mechanisms and must fully comply with international safety standards (CE, ISO, ANSI, etc.).

Evaluate the appropriate packaging robot solution

When choosing a robot, businesses need to consider practical factors in production operations such as:

- Production volume: Determine the total number of products to be packaged per day, week or month. Analyze average production time, number of working shifts and machine capacity requirements.

- Production speed: Calculate the number of products to be packaged per hour to choose a robot with the appropriate response speed.

- Complexity of the packaging task: If there are many types of products with different sizes and shapes, it is necessary to choose a flexible, easy-to-program robot. For complex tasks (labeling, wrapping, quality inspection), priority should be given to advanced robots or collaborative robots (cobots) that can work safely with humans.

Evaluate the complexity of the packaging task

If a business has many types of products with different sizes, weights or shapes, the robot needs to be able to flexibly adapt to each type of packaging and process. In cases where the packaging process requires high precision or sophisticated operations, businesses should invest in advanced packaging robots that can operate independently or safely coordinate with humans (cobots).

Consider the type of product being packaged

Each robot system has different capacities, payloads, and technical configurations, suitable for each product line. For example, robots specializing in handling light products such as food and cosmetics will be different from robots serving the packaging of heavy industrial products or mechanical components.

Determine the necessary functions and features

If the packaging job is simple, only requiring moderate speed and precision, you can choose a robot with a compact structure, easy to operate and maintain, both saving costs and shortening the payback period (ROI). On the contrary, with complex processes or requiring high customization, businesses should choose multi-purpose robots that integrate smart sensors, machine vision systems, and automatic control software.

Potential Challenges and Mitigation Strategies for Investing in Packaging Robots

Identify Potential Challenges in Deploying Packaging Robots

Before deciding why to invest in packaging robots, businesses need to clearly identify potential challenges to ensure the most effective implementation project:

- Robots are often programmed to perform fixed tasks. When products change in size, weight or shape, businesses may need to adjust or reprogram the robot.

- In many factories, environmental conditions such as temperature, humidity or dirt. Packaging robots need to be designed to operate stably to ensure the continuity and durability of the equipment.

- Robots often operate in close proximity to operators. Therefore, built-in safety solutions, such as collision detection sensors or work zone limits, are needed to avoid accidents and ensure a safe and efficient working environment.

- Investing in packaging robots requires a relatively large initial capital, including the cost of purchasing equipment, integrating the system, training employees and regular maintenance. This is a long-term investment, bringing positive ROI if planned in the right direction.

- Applying robots requires a team of employees to master the skills of operating, monitoring and maintaining the automated system, which may be difficult at first but is a necessary step to upgrade modern production capacity.

Risk mitigation strategy when deploying packaging robots

To ensure that the investment and deployment of packaging robots goes smoothly, businesses need to develop a risk mitigation strategy:

- Identify factors that may affect the progress, cost and efficiency of the project. Prioritize handling risks with high impact and high probability of occurrence.

- Classify risks by type: technical, financial, human resources, operational or organizational culture. Understand the causes and consequences to propose appropriate control measures.

- Propose specific prevention and remediation solutions for each type of risk. Apply simulation tools, test robots in virtual environments before putting them into practice to reduce errors.

- Develop a detailed response process in case of an incident. Determine resources, personnel and processing time to quickly restore production operations.

Popular types of automatic packaging machines today

When businesses are looking for reasons to invest in packaging robots, one of the important factors to consider is choosing the right packaging machine for their production needs. Below are some popular and highly effective devices in modern factories.

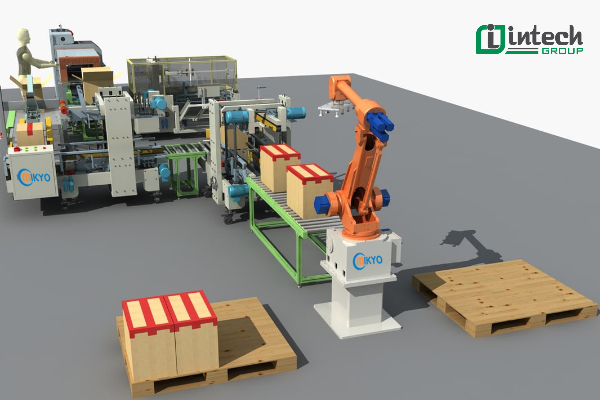

Palletizing Robot Station

Palletizing Robot Station is a device that integrates smart industrial robots, capable of automatically loading or unloading goods from pallets with high speed and accuracy. Outstanding advantages:

Reduce manual labor and limit the risk of accidents during loading and unloading.

Increase packaging and shipping efficiency, especially in factories with high output.

Easy to program for many different sizes and types of products.

Helps optimize storage space and synchronize the automatic process of the production line.

Robot loading and unloading stations are currently being researched, developed and manufactured by Intech Group according to the requirements of each business, ensuring flexibility - safety - high investment efficiency.

.jpg)

Automatic Pallet Wrapping Machine

Efficiency and consistency are key to the packaging process. Manual pallet wrapping often results in inconsistencies and wastes manpower.

With an automatic pallet wrapping machine, the entire process is fully automated, helping to:

- Ensure goods are wrapped tightly, securely and evenly.

- Minimize manual intervention.

- Improve packaging speed, increase productivity and reduce labor costs.

- Help protect products during storage and transportation.

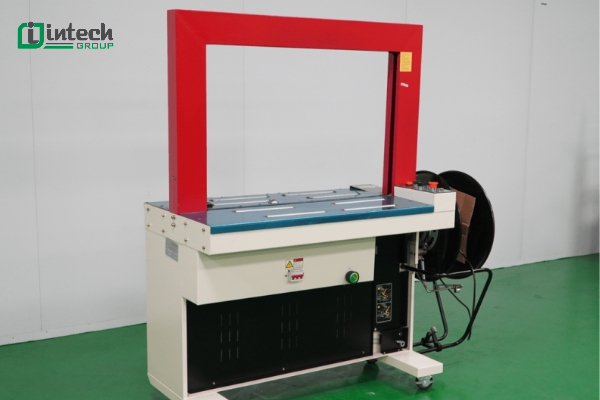

Automatic strapping machine

Automatic strapping machine is an important device in the packaging robot system, helping to tighten and fix products with plastic or steel straps. Benefits of using automatic strapping machine:

-

Increase productivity many times compared to manual operation.

-

Sensors automatically detect and feed straps, helping the process to take place continuously.

-

Reduce machine downtime, limit human errors.

-

Ensure accurate and stable tightening force for each package.

Automatic carton sealer

Automatic carton sealer helps businesses fully automate the carton packaging process, bringing high productivity and consistent quality. Outstanding advantages:

- Fast, accurate and uniform carton sealing, limiting errors compared to manual sealing.

- Reduce labor costs, optimize production time.

- Easy to integrate with conveyor belts, carton picking robots or automatic loading and unloading stations.

- Ensure the aesthetics and sturdiness of packaging, contributing to enhancing brand image.

Thanks to its stable operation and labor-saving capabilities, automatic carton sealers are increasingly widely used in packaging lines for consumer goods, electronics, food, pharmaceuticals, logistics, etc.

Conclusion

Automatic packaging equipment such as robot loading stations, pallet wrapping machines, strapping machines and carton sealing machines not only help businesses reduce operating costs and improve production efficiency, but also create sustainable competitive advantages in the era of industry 4.0.

If you are wondering why you should invest in packaging robots, contact Intech Group - a consulting, design and implementation unit for comprehensive packaging automation solutions, helping your business operate intelligently - economically - effectively in the long term.