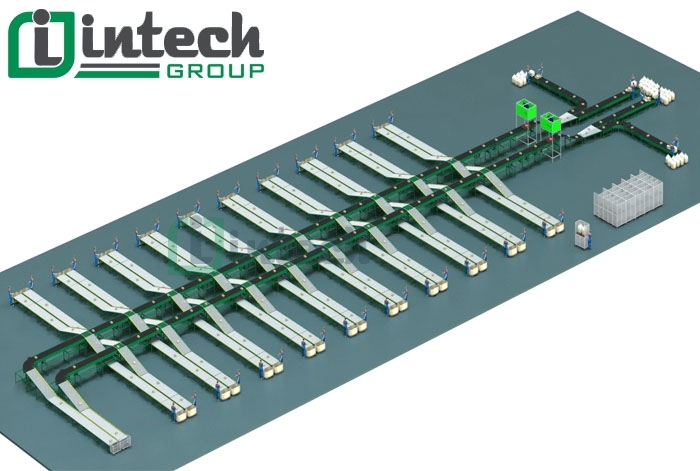

* Working principles of the sorting system:

|

- The sorting system at the lower level will collect information about the barcode + size + weight of the product and then send that information to the data server above the server, from which the data is processed and responded to the control server.

- This information is analyzed by the server in response to the product's information sorting system and issued to the actuators.

- Depending on the sorting programming, the products go to the door corresponding to the sorting turn.

- All information data is saved at the server, saved on the Sever in real time, helping the data management to be consistent as well as giving development strategy orientation in line with market trends.

- A center for mining and sorting can be equipped with a remote monitoring, operation and control system, through current connected devices, actuators and IoT technology, depending on its size and requirements.customers' needs that we will offer appropriate and optimal solutions.

- The Scaner system can process, read and analyze Bacode 1D, 2D,…depending on the customer's Code base, we also offer appropriate device configuration.

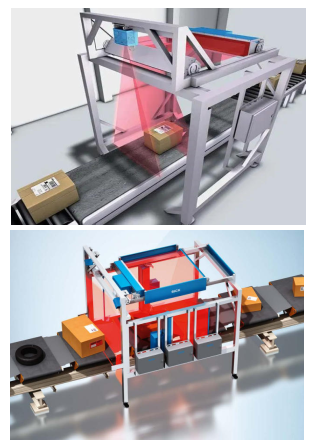

- In addition to an ordinary system that has the function of sorting parcels, then making statistics, synthesizing and storing common data, we also have advanced solutions, which are the DWS system (DWS system:Dimention - Weigher - Scaner) is a system that integrates parcel dimensioning equipment, automated parcel weighing and automated barcode reading (Bacode) and then synthesizing, comparing and contrasting the inputdata (parcel receiving) to give warnings and errors of the parcel.In addition, the data is also saved on the host computer and on the Sever in real time, retrieved when needed.

See more:

- Cross belt sorting system - Sorter

- Vertical Crossbelt Classification System

What is DWS?

|

D - Dimension: Measures the size of the object.

W - Weigher: Measures the volume of the product

S - Scanner: Reads the product's barcode information.

The Dimension, Weigher and Scanner (DWS) is a highly effective solution to calculate the weight and size of parcels for efficient exploitation and providing necessary informationfor the purpose of arrangement, optimal use of space in the vehicles or suitable temporary storage locations.

The DWS system is located at the input part of the classification system to collect data, get information about the door of the parcel before the classification system at the lower level proceeds to classify the goods.

DWS (Dimention - Weigher - Scanner) function:

- The sorting system at the execution level will collect information about the barcode + size + weight of the product and then send that information to the data server at the top which is the control system (Several server).

- This information is analyzed by the server in response to the product sorting system.

- Information about the size & weight of the products is stored at the customer's server for the purpose of retrieving data about the products to serve different operations...

- Depending on the sorting programming, the products go to the door corresponding to each pre-programmed sorting turn.

- Storing all data at the server will help to keep the data management consistent and accessible anytime, anywhere, helping customers to make analysis and then adjust the orientation.development strategy in line with the market in stages.

What is WCS?

WCS is software that controls and controls automated sorting systems in warehouses or distribution centers.This system coordinates implementation-level sub-components such as conveyor systems, conveyor belts, weighing stations, and sorting equipment.At each decision point, WCS determines the most efficient product flow and transmits instructions to the implementation components to achieve the desired best results.

WCS management and control software:

.PNG)

Products of the same category

-

Pop-Up sorting system

Designed for moving and sorting large packages and weighing up to 35kg with independent operation, stability, energy saving, and low maintenance costs;

-

Vertical Crossbelt Sorting System

The highlight of the vertical crossbelt sorting system is that it saves space.Only 2.5 m wide space is enough to install this type of Crossbelt sorting system.

-

Wave-Sorter sorting system

The Wave-sorter sorting system is a very popular module nowadays, widely applied in the commodity classification industry, it has the ability to classify up to 10,000 products/hour.

-

Cross belt - Sorter sorting system

Cross belt - Sortersorting system is a very popular module today, widely used in the goods sorting industry, with the ability to sort at high speed up to 25,000 products/hour.

-

Overview of sorting system

The sorting solution includes automated DWS information extraction devices & a product distribution system to each specific outlet.