WHAT IS AUTOMATEDSORTING SYSTEM?

The sorting system is an industrial solution that replaces humans to perform the product sorting stages, from manual work to the use of automated systems to divide products according to the characteristics that people use.use regulations.The sorting is usually done based on the information source from the barcode attached to the product, when retrieving data from the server, it will give information about the doors corresponding to a predefined address.

The sorting solution includes automated DWS information extraction devices & a product distribution system to each specific outlet.In the current era of the 4.0 technology revolution, the application of smart sorting solutions is extremely necessary, they help to free up labor and improve the management capacity for mining centers.(DWS system : Dimention - Weigher - Scaner)

Advantages of the parcel and productsorting line system:

|

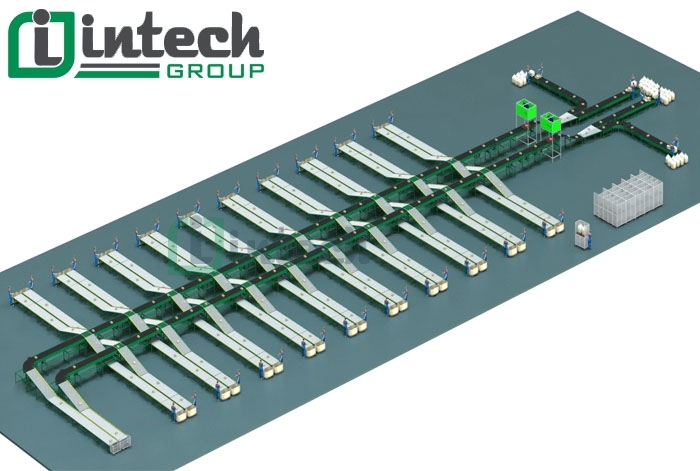

- Design solution: Automated sorting system including data mining devices (bar code information, weight, and size) from products & a system to divide products to each specific address according toa programming has been installed according to the needs of each customer, each specific time.

- Design optimization: Depending on each criterion of output, installation space, workshop area... of each specific customer, the appropriate sorting technology will be selected in the form of Horizontal Crossbelt or Vertical Crossbelt, Wave.Sorter or Pop-up Sorter ... A floor or two layers of classification at the same time will optimize the design solution, cost.

- Long-term benefits: In the current era of 4.0technological revolution, the application of smart automatedsorting solutions is an inevitable trend, helping to free up labor, increase productivity, and improve accuracy, thereby improving management capacity for distribution centers of all industries

Thanks to the application of the parcel sorting system, Logistics enterprises have had a competitive advantage, maximized the parcel sorting process, increased automation, and created a professional working environment with low costs.Reasonable investment fees.Intech has researched and launched sorting systems with high accuracy and capacity that can reach up to 25,000 products per hour, accurate speed, very low error rate in the sorting process below 0.01%, the system can operate continuously;

Intech is one of the leading technology companies in Vietnam developing a parcel sorting linesystem with Crossbelt Sorter, Wave sorter or Pop-up technology, applying high-speed "Barcode" reading technology on each parcel.The systems are applied IoT connection technology to operate, check, monitor and manage data remotely.The data is stored on the server automatically in real time, which can be automatically analyzed and compared to give automatic warnings about the status of goods and thereby give appropriate strategies for Logistics activities.of his company;

The automated parcel sorting system is widely applied in courier (CEP) and e-commerce enterprises and modern industrial factories;

|

Types of sorting systems of Intech Group

- Cross belt sorting system - Sorter

- Vertical Crossbelt Sorting System

- Pop-Up sorting system

- Wave-Sorter sorting system

Applications of the sorting system:

- Express delivery industry

- Light industry

- Garment industry

- Pharmaceutical industry

Project implementation process:

In the current era of the 4.0technology revolution, the application of smart automatedsorting solutions is an inevitable trend, helping to free up labor, increase productivity, improve accuracy, thereby improving management capacity of distribution centers of all economic sectors.Contact us now for advice and solutions that are right for your business.See more:

- Control system and connection

- Cross belt sorting system - Sorter

Products of the same category

-

Pop-Up sorting system

Designed for moving and sorting large packages and weighing up to 35kg with independent operation, stability, energy saving, and low maintenance costs;

-

Vertical Crossbelt Sorting System

The highlight of the vertical crossbelt sorting system is that it saves space.Only 2.5 m wide space is enough to install this type of Crossbelt sorting system.

-

Wave-Sorter sorting system

The Wave-sorter sorting system is a very popular module nowadays, widely applied in the commodity classification industry, it has the ability to classify up to 10,000 products/hour.

-

Cross belt - Sorter sorting system

Cross belt - Sortersorting system is a very popular module today, widely used in the goods sorting industry, with the ability to sort at high speed up to 25,000 products/hour.

-

Control and connection system

The sorting system at the lower level will collect information about the barcode + size + weight of the products and then send that information to the database server above the server.