ROBOT SHUTTLE - ROBOT PALET SHUTTLE - SOLUTION TO INCREASE BUSINESS GOODS FLOW

WHAT IS ROBOT SHUTTLE?

Robot Shuttle is the main technological device that makes the name of the modern 4.0 pallet shuttle warehouse. This line of robots does not operate independently but is used to attach to the iron rack system to support goods, through the guide rails of the radio shuttle shelf, the robot can move safely and accurately

Other definition: Robot shuttle or also known as robot pallet shuttle or automatic pallet shuttle is one of the important parts in the radio Pallet Shuttle warehouse shelf system or pallet shuttle warehouse to help transport goods to the shelves in an optimal way. This is a line of robot equipment on the rail in the storage lane to load and unload goods using pallets combined with forklifts.

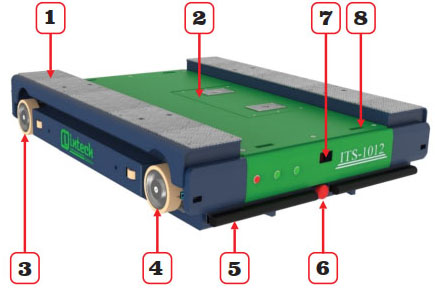

ROBOT SHUTTLE STRUCTURE

The pallet shuttle robot is designed with high speed, equipped with various safety devices with the following sentences:

|

1. Pallet lifting and lowering unit

2. Lithium battery unit

3. Guide wheel unit

4. Drive wheel unit

5. Safety sensor

6. Emergency stop button

7. Distance sensor

8. Pallet check sensor

REALISTIC ROBOT SHUTTLE IMAGE

Image of shuttle robot installed on shuttle warehouse shelf

Image of shuttle robot on shuttle warehouse shelf

FEATURES OF ROBOT SHUTTLE

-

It is an automatic moving device on the shelf lane to stack, import or unload goods

-

Auto shuttle ensures high-density storage, maximizing storage space on the radio shuttle shelf through the flow/frequency of loading and unloading goods on the shelf.

-

Wifi shuttle robot uses wifi control and warehouse management software between control devices used for AGV robots. Or use remote-controlled shuttle robots, this is the most popular line because it is easy to use.

-

The robot line is improved from the AGV self-propelled vehicle line (AGV Robot) in automatic pallet storage instead of the traditional drive-in warehouse system.

-

The shuttle pallet vehicle is capable of independent operation, controlled by a simple remote combined with an LED display screen with a variety of installation languages.

-

Pallet shuttle robot can run all lanes of automatic warehouse shelves, LIFO (last in first out)-FIFO (first in first out) mode

-

The vehicle operates stably in cold environments -30℃

Products of the same category

-

ITA-02 Conveyor Integrated Transport Robot

The ITA-02 integrated conveyor transport robot is a robot used to move or transport goods, components or products. The vehicle is also integrated with a roller conveyor on its back, which can automatically load and unload goods.

-

ITA-03 Conveyor Integrated Transport Robot

The ITA-03 conveyor integrated transport robot is an upgrade of the ITA-02 series used to move or transport goods, components or products.

-

AGV ITA-01 Autonomous Robot

The AGV ITA-01 self-propelled robot is the most basic AGV robot in the AGV line. Its function is simply to pull goods. The goods are connected to the AGV through a fixed pin on the vehicle.

-

AGV ITA-02 Autonomous Robot

The AGV ITA-02 is a small, multi-functional AGV robot. It moves under the truck or in front of the truck, and connects to the truck with 1 or 2 pins on the body.

-

ITA-02 Cargo Pulling Robot

The ITA-02 towing robot is a small, multi-functional AGV autonomous robot. The vehicle moves under the truck or in front of the truck, connected to the truck by 1 or 2 pins on the body.

-

IT-AGV-C – AGV with a conveyor belt on its back

IT-AGV-C Self-propelled robot is a type of robot used to move or transport goods, components or products.The vehicle is also integrated with belt conveyor or roller conveyor on the back, which can automatically load and unload goods.

.jpg)