What is a food packaging machine? Features and Classification

06-10-2025 26

Food packaging machines are important equipment in the processing industry, helping to accurately measure, preserve food and extend its shelf life. Whether it is fresh food or dry food, the automated packaging process helps increase production efficiency and ensure food hygiene and safety.

What is a food packaging machine?

A food packaging machine is an important device in the production line, helping to accurately quantify, quickly package and optimally preserve food. This device automatically puts food into specialized packaging, seals it tightly and moves it to the next stage, ensuring food hygiene and safety and prolonging the time of use.

How does a food packaging machine work:

Step 1: Put food into the packaging according to the correct quantity.

Step 2: Seal the surface of the package, ensuring it is secure.

Step 3: Transfer the product to the next stage.

With modern automation process, food packaging machine not only helps increase production productivity but also ensures product quality and consistency.

Outstanding features of food packaging machines

Food packaging machines have many modern features, helping to increase productivity, ensure quality and food hygiene and safety. Below are the outstanding features:

- Fully automated: Operates precisely, at a speed 3-4 times higher than manual machines, helping to save time and labor.

- High-quality materials: The entire machine is made of stainless steel, anti-corrosion, does not release toxic substances, meeting food safety standards.

- Optimal design: Integrated with a half-cut feature, making it easy to tear the product apart; sturdy stamping technology, creating beautiful and durable packaging.

- Diverse applications: Suitable for packaging many types of food such as tea bags, candies, dry foods..., bringing flexibility to businesses.

- Smart system: Automatically recognizes and stops operation when problems such as too high or too low temperature occur. Errors will be displayed on the screen, helping users to easily monitor and handle them promptly.

With outstanding advantages, food packaging machines are the ideal choice to help businesses optimize production processes and improve product quality.

Popular types of food packaging machines today

Food packaging machines are designed in a variety of ways to suit each type of food, helping to preserve products better and optimize the production process. Below are the most popular types of food packaging machines:

1. Vacuum machine

Vacuum machines create an airtight environment by completely removing the air inside the packaging, helping to preserve food 3 to 5 times longer than conventional methods. Vacuuming prevents the growth of microorganisms, keeping the freshness of foods such as meat, fish, seafood, vegetables, etc.

2. Candy packaging machine

The candy packaging machine helps maintain crispness, prevents mold thanks to the digital temperature controller, ensuring product quality throughout the storage process. In addition, the automatic counting system helps control the quantity of products in each package, optimizing the production process.

3. Bottle capping machine

This is an important equipment in the beverage, beer, wine, and canned food production industry. Bottle capping machines are often integrated in automatic filling and packaging lines, helping to improve productivity and ensure product quality.

4. Vertical packaging machine

Vertical packaging machine is suitable for many types of food such as powder, seeds, spices, etc. The machine operates according to the automatic process: bag making - pouring product according to quantity - sealing the bag, ensuring the product is safely protected during transportation and storage.

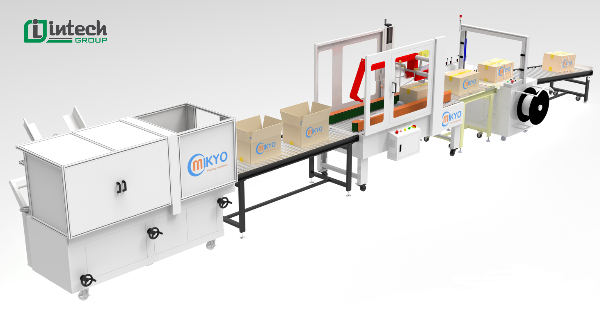

5. Automatic carton packing machine

Carton packing machine is widely used in the food industry, helping to pack products into cartons quickly and securely. This equipment helps save labor, reduce operating costs and enhance the professionalism of the production line.

Choosing the right packaging machine not only helps businesses improve efficiency but also ensures that products are better preserved, meeting food safety and hygiene standards.

Comparison of manual packaging machines and automatic packaging machines

The choice between manual packaging machines and automatic packaging machines depends on the production scale, investment costs and operating needs of the business. Here are the main differences between these two types of machines:

| Criteria | Manual packaging machine | Automatic packaging machine |

| Operating mechanism | Depends on human operation, low productivity | Automatic operation according to programming, increasing efficiency |

| Packaging speed | Slow, prone to errors | 3-5 times faster than manual |

| Accuracy | Difficult to control uniformity in packaging weight and size | Accurate quantification, ensuring product quality |

| Labor costs | Need a lot of labor, increase operating costs | Reduce labor, save long-term costs |

| Safety and hygiene | Vulnerable to bacterial contamination due to frequent contact with food | Meet food hygiene standards, limit external agents |

| Application | Suitable for small-scale, small-scale production facilities | Ideal for large, high-capacity production enterprises |

| Durability and maintenance | Easily damaged due to frequent manual use | Long life, stable operation |

Intech Group - Supplier of carton packing machines, automatic product packing lines

Intech Group is a supplier of carton packing machines and automatic product packing lines, helping businesses increase productivity, reduce operating costs and ensure consistent quality.

With comprehensive automation solutions, businesses can easily expand production scale, meet market needs quickly and professionally. Intech Group not only provides modern packaging equipment, but also designs smart production lines, suitable for many industries such as food, pharmaceuticals, electronics and logistics. Contact us now for advice on the optimal solution for your business!