What is Delta Robot? Application of Delta Robot in manufacturing industry

14-10-2025 3

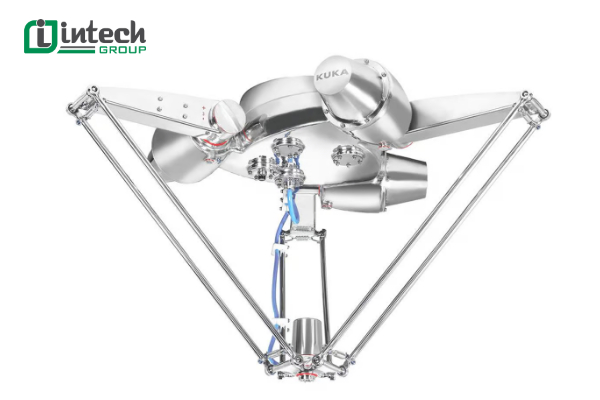

The delta robot is a parallel robot with three arms, each attached to fixed rotary joints on a platform. The distinctive design of this robot lies in the use of parallelogram arms, which help maintain a fixed orientation for the end-effector to change direction more flexibly.

What is a Delta Robot?

A Delta robot, also known as a spider robot, is a line of industrial robots with a special design and is different from traditional fixed industrial robots. The name Delta comes from its upside-down triangular shape, creating a quite characteristic structure. The Delta robot system is installed on the work area and is controlled by large sweeping arms. The robot's gripper (working arm) is connected to long and slender mechanical links, which help to perform flexible operations.

These links connect to three or four large motors located at the robot's feet. Sometimes, delta robots are also equipped with additional motors to increase the degrees of freedom of the gripper, helping to perform more precise tasks.

Applications of Delta Robots

Delta robots are often used in industrial applications that require precision, high speed and flexible manipulation. Some typical applications of delta robots include:

Pick and place: Moving objects accurately and quickly, especially in automated production lines.

Assembly: Assembling small components with high precision.

Disassembly: Dismantling parts from structures or products.

Packaging: Packing products into packaging, especially in the food or pharmaceutical industry.

Sorting: Arranging items and components as required during the production process.

Thanks to their unique design and ability to operate with high speed and precision, delta robots are an optimal solution in many modern industries.

Advantages and Disadvantages of Delta Robot System

-

Advantages:

Delta Robots are known for their outstanding operating speed, which is one of the key factors that makes this system the top choice in high-performance manufacturing applications. Designed with motors placed parallel to the work surface, Delta Robots can perform tasks at speeds that traditional industrial robots cannot match. This speed is especially important in mass production industries where time and productivity are always at the forefront. Therefore, Delta Robots are the ideal solution for production lines that require precision and high speed.

In addition to speed, the unique design of Delta Robots is also a strong point. The motors are integrated into the robot's base with high IP standards, protecting the robot from dust and moisture, helping it operate durably in harsh industrial environments.

Another notable advantage of Delta Robots is the ability to make optimal use of workspace. With its compact design and arms mounted above the workspace, the Delta Robot can operate in areas with limited space. This frees up floor space for other equipment and additional storage, making a difference in manufacturing plants where floor space is at a premium.

-

Disadvantages:

While the Delta robot offers many outstanding benefits, there are also disadvantages to be aware of. One of the biggest weaknesses is its reach and payload. Due to the robot's mechanical design, the Delta Robot cannot carry or move heavy objects, which limits its application in some industries that require the movement of large materials.

In addition, the Delta Robot's operating range is also limited. Its mechanical structure, with grippers connected via long shafts, creates a conical shape, making it difficult for the robot to move downwards. This reduces its reach in areas with depth or requires moving objects in low positions.

In which manufacturing industries are Delta Robots used?

Automation is becoming an important trend in modern industries to maintain competitiveness and production efficiency. Delta Robots bring outstanding advantages to help companies in many industries optimize production processes. Common manufacturing industries using Delta Robots include:

- Food industry

-

Beverage industry

-

Consumer goods industry

-

Retail packaging industry

-

Pharmaceutical industry

-

Cosmetic industry

- Additives industry

In these industries, Delta Robots are mainly used to achieve extremely high production speeds, up to 300 products/minute. This outstanding speed helps factories maintain high productivity and meet market demand. Another notable advantage is the robot housing design, where the motors are completely housed within the robot base, achieving a high IP rating, ideal for environments requiring high levels of protection such as in the food and beverage industry. The delta robot, with its IP69K rating, is an ideal choice in factories requiring strict hygiene standards.

When to Automate with Delta Robots?

So when should you consider automating your production with delta robots? To make the decision, you need to evaluate the business challenges and problems in your current production process. Delta robots often bring significant improvements in the following factors:

-

High quality: Delta robots help maintain and improve product quality.

-

High automation: Minimize human intervention and improve production efficiency.

-

High safety: Improve worker safety during production.

-

High efficiency: Increase productivity and reduce waste.

-

High flexibility: Easily adapt to changing production processes and different product requirements.

If you are looking to improve productivity, quality, and flexibility in production, delta robots are the optimal solution to meet these requirements.

Benefits of Delta Robots in Manufacturing

1. Production Productivity

Delta robots provide significant productivity gains compared to manual processes. For example, in the biscuit bar industry, switching to Delta Robots for packaging can increase production rates and reduce product transit times, thereby increasing revenue. However, the entire production process needs to be evaluated to optimize the deployment of robots.

2. Production Efficiency

Delta robots are more efficient than manual labor, not only faster but also more accurate and consistent in performing repetitive tasks without taking breaks. This helps maintain stable productivity throughout the production process.

3. Quality Control

Delta robots ensure high precision in assembly tasks, especially in the electronics industry. They operate with a level of consistency, minimizing human error, resulting in stable product quality over time.

4. Cost of Delta Robot

The cost of purchasing a Delta Robot ranges from $20,000 to $50,000, however, additional implementation costs such as system integration, risk mitigation, and maintenance can increase the total cost. Specifically:

-

Integration: Costs may vary depending on the complexity of the application and the time of installation.

-

Risk mitigation: Investment in safety measures such as fences, sensors, and status indicators is required.

-

Maintenance: Regular maintenance such as lubrication, replacement of wear parts, and system inspections helps prolong the life of the equipment and ensure long-term operational efficiency.

-

The total cost associated with maintaining a Delta Robot will help you accurately calculate ROI and make a wise investment decision.

With over 14 years of experience in the industrial sector, Entech Group provides automation solutions combining picking and unloading robots for manufacturing plants nationwide. In the process of promoting industry 4.0 with the criteria of industrialization and modernization, Intech Group is a pioneer in the field of factory automation. Please contact us via Hotline 0966.966.032 - 0986.448.456 to receive solutions for your factory.

See other robot lines: Robot AGV, Bag Loading and Unloading Robot