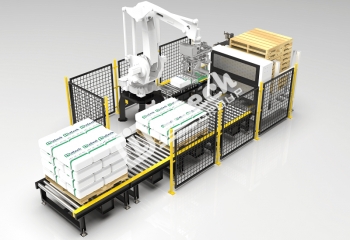

With many years of experience in providing automation solutions in production and linking to deploying and installing smart factories for many leading partners in the world.We provide a fully automatic industrial robot system for loading and unloading pallets to customers, with many preeminent features and effective applications in production.In addition, with the diversity of robot product lines loading and unloading pallets.Intech Group wishes to be able to provide you with an automated solution for loading and unloading goods.

In addition to industrial robots, we also provide customers with accompanying software systems to help automate machinery equipment, production lines or more easily to optimize production processes, improvehigh competitiveness compared to competitors.

What are industrial robots?

A robot is a programmed machine capable of helping humans to perform tasks automatically. Industrial robots are used for the purpose of assembly, production, ... with high accuracy and efficiency superior to manual production.

Some standards of industrial robots:

- Standard RIA of America (Robot institute of America): Used to move materials, parts, tools, or specialized devices.

- French AFNOR standard: Capable of locating, orienting, and moving physical objects such as details, props, jigs, etc.

- Russian standard TOCT 25686-85: Helps to complete motor and control functions during production.

Intech - Specializing in providing industrial robot solutions

As a specialized unit, we have many industrial robot solutions suitable for each customer's needs such as:

- The robotic solutions for loading and unloading goods in bags onto pallets;

- The robotic solutions for loading and unloading goods in boxes onto pallets;

- The robotic solutions for loading and unloading goods in blocks or boxes onto pallets;

- Robotic solutions for loading and unloading special, malformed, deformed goods... onto Pallets.

Solutions

Intech Group chooses robots according to the needs of customers with the following solutions:

- Overall solution design: designing conveyor belts, robots, automated pallet feeding, moving pallets to another location after loading.

- Handling design: Using Servo or pneumatic depending on the type of product to be picked up.

- System simulation and design: Providing optimal solutions for robot operation and ensuring safety when operating.

Specifications

- Lifting capacity: 80 - 800kg

- Speed: 20 bags/min (for 50kg bags)

- Depending on your needs, you can choose the type of robot: There are 6 types of robots corresponding to 6 different automatic loading and unloading systems.

- Easy to install and train the robot thanks to the software system provided

Benefits of industrial robots for automatic loading and unloading

Benefits brought to customers from Intech Group's Industrial Robot System of Automated Pallet loading and unloading:

- Increasing safety in production;

- Increasing productivity in production;

- Creating professionalism and automation in production;

- Avoiding people working in heavy and hazardous loading and unloading environments;

- Quick returning on investment (only from 1 to 2 years);

Choosing the right deploying unit, dedicated advice and high professional skills will help businesses save costs in deploying the Industrial Robot System of Automated Loading and Unloading, making the most of the benefits that intelligent production can bring.Contact Intech Group for advice. Holine: 02466 806 795.

-

IT- PLT-CN-01 Automated palletizing system

The palletizing system of goods in cartons includes one input and one output.Using 3-axis transfer assembly, automated pallet feeder assembly and film wrapping.

View Packing -

IT-PLT-CR-03 Automated palletizing robot system

Thepalletizing system of goods in cartons includes two inputs and one output.Using a picker robot, automated pallet feeder and automated film wrapping machine.

View Packing -

IT-PLT-CR-02 Automated palletizing robot system of goods in bags

System of picking and palletizing products in the form of boxes, including two inputs and output.Using automated picking robot and pallet assembly, and outputfilmwrapping machine.

View Packing -

IT-PLT-CR-01 Automated palletizing robot system

The system of picking, loading and unloading carton goods onto pallets, including two inputs and outputs.Using picking robot and automatic pallet feeder assembly.

View Packing -

IT-PLT-BR-02 automated palletizing robot system of goods in bags

IT-PLT-BR-02 automated palletizingrobot of goods bags uses automated picking robot and pallet assembly, and output film wrapping machine

View Packing -

IT-PLT-BR-01 Automated palletizing robot system

The system of picking and palletizing products in the form of a bag, including an input and an output.Using automated picking robots and pallet assemblies.

View Packing -

Connecting and controlling the loading and unloading robot system

Intech Group provides automated palletizing robot control systems. This solution effectively applied, increasing productivityand be professional in production.

View Packing -

Options of pallet loading and unloading system

The pallet loading and unloading system helps equipment and production lines to optimize processes and improve competitiveness.

View Packing -

Overview of automated loading and unloading robot system

Automated palletizing robots are a semi-automated and fully automated solution the loading and unloading process.

View Packing