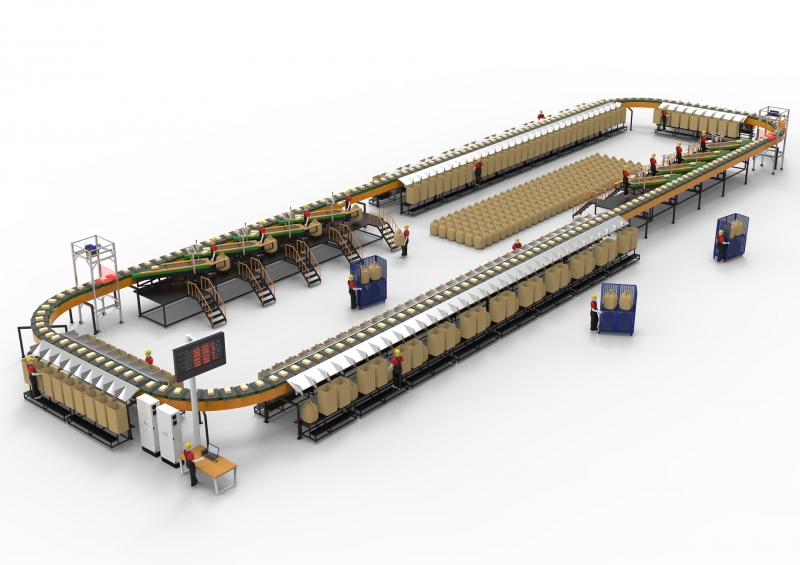

The pet bottles are transported by the conveyor system through the following stages:

1- Printing date and code: at this stage, there will be a camera to check the date, error code and remove the error printed bottles,

2- Filling: The pet bottles are filled and quantified by volume at the filling heads

3- Capping: At this stage, the bottles are closed and sealed

4- Weighing: Re-quantifying the bottles by weight to compare with stage 2. Here the bottles with volume and weight that do not meet will be discarded.

5- Carton packing: At this stage, the bottles will be packed into cartons according to the quantity of 20,24 bottles/1carton

6- Weighing cartons: The cartons after stage 5 will be re-checked for weight to eliminate defective boxes due to lack of bottles...

7- Closing the pallet: At the palletizer cluster, the boxes will be picked up by the robot and stacked on the pallet, then wrapped with protective film at the output of the system.

Applications: Widely applied in the field of food, chemicals…, helping to reduce labor, increase productivity, and eliminate errors and risks of foreign objects falling due to human operation

Please contact us immediately for advice on Bottling Line and smart factory solutions!

See more:

- Transporting and packing systems

- Sewing machine assembly line

Products of the same category

-

Automated bottling system

Automated bottling system brings quality products;for the convenience of customers, Intech has brought to market a fully automated system.

-

Conveying and packing systems

The conveying and packing system helps to pack and transport products automatically with hermetic double line, bringing high efficiency.

-

Pallet conveyor system

Pallet conveyor system includes: Pallet conveyor, Lifting mechanism, Roller, conveyor belt... Based on customer requirements and purposes such as: pallet wrapping, packing, shipping to warehouses, storage of input and outputdata.

-

Sewing machine assembly line

The sewing machine assembly line has completely different features from other traditional assembly lines to help improve efficiency and optimize the assembly process.

-

Pallet retrieval conveyor line

Intech offers solutions ranging from simple to highly automated, such as automated pallet storage and retrieval systems (ASRS), automation guided vehicles (AGVs), sorting technology and smart conveyors.

-

Automated Goods Sorting System

Choosing a unit with high expertise will help businesses save costs and time when deploying an automatic goods sorting system. Please contact Hotline: 02466 806 795 of Intech Group for free advice on automated goods sorting solution!