- With more than 30 complex assembly stages, each stage takes a long time, to complete a sewing machine assembly (up to the time of packaging, including testing) about 30-45 minutes/1 machine

- Weight ranges from 40-50kg/machine for each sewing machine.

- Pure oil environment, there are stages, the inside of the machine is coated with oil.

- After completing the assembly, the machine will be transferred to the testing phase.

With the above characteristics, the sewing machine assembly line must meet the following conditions:

- Conveyor speed only fluctuates 1-2m/min, but do not run jerkily, jerking will make the operator dizzy.

- The surface and structure must be secure, because when the worker puts the machine down, a large impact force will cause the conveyor surface to deform over time.

- Conveyor surface damping material must be prime oil resistant, otherwise after a while, the damping plastic will swell.

- A rather long sewing machine assembly line, which needs to be alternated by elevators that move the machine over the head, to serve travel.

* Features:

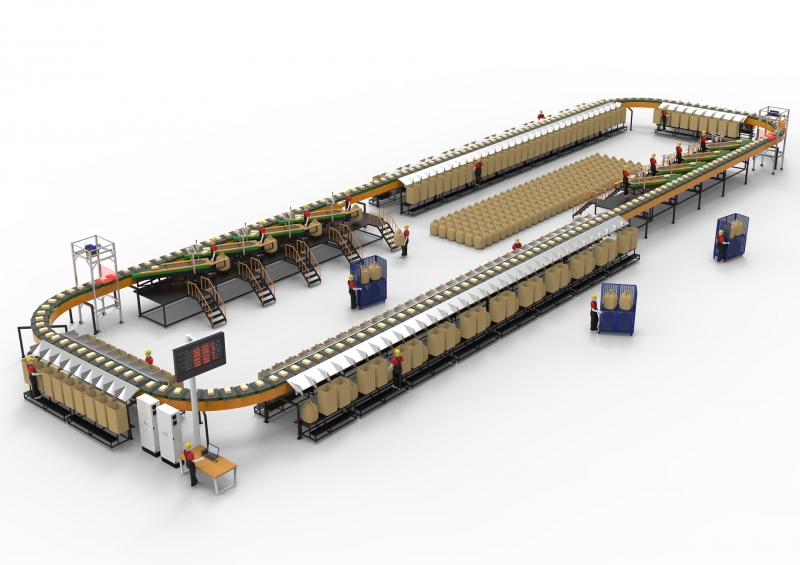

As part of the assembly and inspection of sewing machines. The sewing machines are assembled on a chain conveyor according to the flow. After the assembly stage, the machines are conveyed to the machine changer to move to the checking stage. At the checking stage, workers check the machine at 8 function check points.

Common applications with semi-automated lines in assembly and inspection have the following advantages:

1- Forming a seamless line according to the flow, minimizing the error of skipping stages

2- Improving assembly productivity, reduce machine transport operations

3- Supporting labor at all stages

Please contact us immediately for advice on Sewing Machine Assembly Line and smart factory solutions!

See more:

- Auto parts production line

- Pallet Conveyor System

Products of the same category

-

Automated bottling system

Automated bottling system brings quality products;for the convenience of customers, Intech has brought to market a fully automated system.

-

Conveying and packing systems

The conveying and packing system helps to pack and transport products automatically with hermetic double line, bringing high efficiency.

-

Bottling line

It is a closed and fully automated system in all stages. The pet bottles are transported by the conveyor system through the stages.

-

Pallet conveyor system

Pallet conveyor system includes: Pallet conveyor, Lifting mechanism, Roller, conveyor belt... Based on customer requirements and purposes such as: pallet wrapping, packing, shipping to warehouses, storage of input and outputdata.

-

Pallet retrieval conveyor line

Intech offers solutions ranging from simple to highly automated, such as automated pallet storage and retrieval systems (ASRS), automation guided vehicles (AGVs), sorting technology and smart conveyors.

-

Automated Goods Sorting System

Choosing a unit with high expertise will help businesses save costs and time when deploying an automatic goods sorting system. Please contact Hotline: 02466 806 795 of Intech Group for free advice on automated goods sorting solution!